Building a Dedicated Low Salt Index SOP Fertilizer Line

- Efat Elahi

- 2 days ago

- 5 min read

Table of Contents

The Premium Market for Low Salt Index SOP Fertilizer

Core Requirements for a Dedicated Production Line

Selecting the Right Machinery: The LANE Heavy Industry Advantage

The Production Process for Low Salt Index SOP Fertilizer

Ensuring Quality: Control, Standards, and Best Practices

Conclusion: Investing in Specialized Production

Frequently Asked Questions (FAQ)

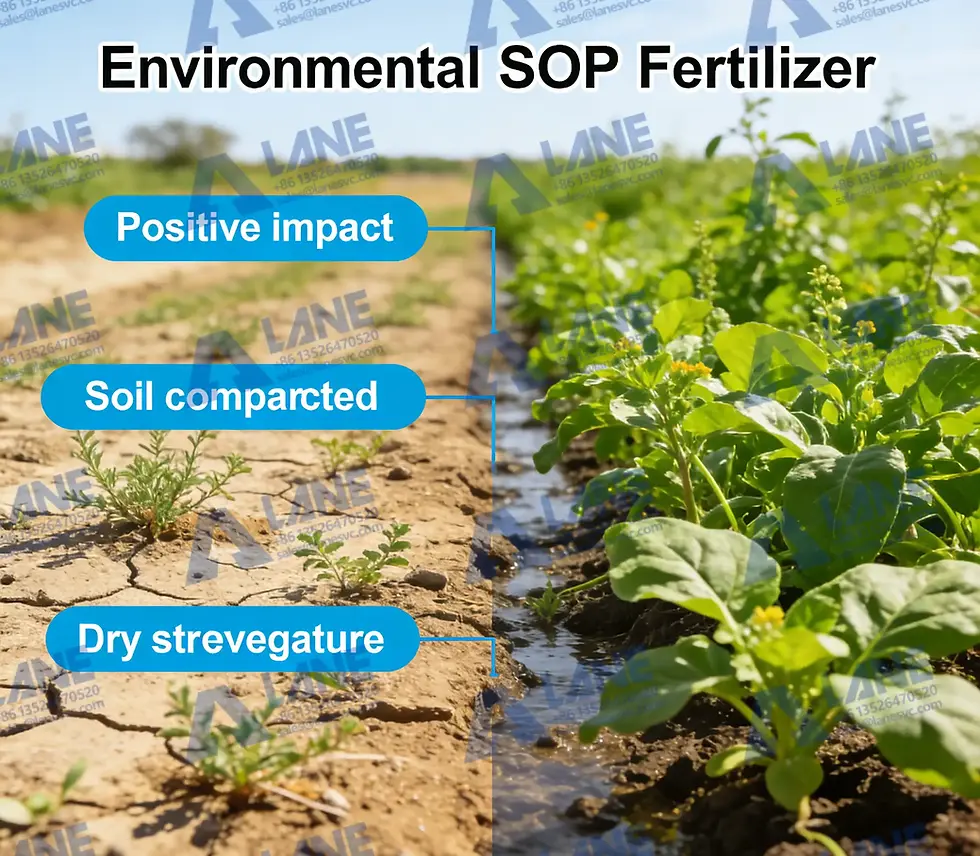

1. The Premium Market for Low Salt Index SOP Fertilizer

The demand for specialized high-efficiency fertilizer is rising due to the increasing demand of high yield and quality produce. Low Salt Index SOP is a premium product distinguished by its agronomic benefits and environmental compatibility. Standard fertilizers can contribute to soil salinity and compaction over time but a Low Salt Index SOP Fertilizer is engineered to mitigate that risk. It has the lowest salt index among potash fertilizer (recorded at 46.1). SOP fertilizer is ideal for chloride-sensitive crops like fruits, vegetables, tobacco, and nuts.

Compared with traditional high-salt fertilizers, Low Salt Index SOP Fertilizer protects the root microecology, improves nutrient absorption efficiency, and contributes to sustainable agricultural development. But to creating Low Salt Index SOP Fertilizer is complex and it requires dedicated SOP fertilizer Production line.

2. Core Requirements for a Dedicated Production Line

A facility dedicated to producing consistent, high-quality Low Salt Index SOP Fertilizer must be designed with precision from the ground up. Unlike a multi-purpose fertilizer plant, a dedicated line prioritizes purity, precise granulation, and strict process control to maintain the low salt characteristic that defines the product.

Key technical requirements include:

Raw Material Purity: The process begins with high-purity potassium and sulphate sources. Impurities, particularly chlorides, must be minimized to ensure the final product's low salt index and suitability for sensitive crops.

Advanced Granulation Technology: The line must produce uniform, hard granules with excellent physical properties (size, strength, low dust) to prevent caking and ensure ease of handling and application.

Controlled Drying: A gentle, low-temperature drying system is crucial. Excessive heat can degrade product quality or alter the chemical structure, potentially affecting the salt index. Systems using low-temperature hot air are ideal for preserving product integrity.

Integrated Quality Control: In-line sensors and sampling points for real-time monitoring of granule size, moisture content, and chemical composition are non-negotiable for maintaining consistent output.

3. Selecting the Right Machinery: The LANE Heavy Industry Advantage

The backbone of any dedicated line is its machinery. For producers aiming to manufacture Low Salt Index SOP Fertilizer, equipment from LANE Heavy Industry offers a robust and reliable solution tailored to these specific needs. LANE's SOP fertilizer production line is engineered for efficiency and product consistency.

Feature | LANE Machinery Specification | Benefit for Low Salt Index SOP Production |

Capacity | 1 to 10 Tons per Hour | Scalable output to match market demand. |

Core Process | Reaction of potassium and sulphate sources | Designed for the specific chemistry of SOP. |

Granule Size | 2 to 10 mm | Produces the uniform, market-preferred particle size. |

Drying System | Low-Temperature Hot Air | Preserves nutrient quality and prevents hardening that can affect solubility. |

Build & warranty | Stainless Steel Components, 5-Year Warranty | Ensures longevity, reduces contamination risk, and lowers lifecycle cost. |

Certification | CE & ISO Certified | Meets international standards for safety and manufacturing quality. |

The design emphasizes a long service life and low energy consumption, which are critical for maintaining competitive production costs for a premium product like Low Salt Index SOP Fertilizer

4. The Production Process for Low Salt Index SOP Fertilizer

A dedicated line using LANE machinery typically follows a streamlined, integrated process:

Raw Material Feeding & Proportioning: High-purity potassium chloride (or similar) and sulfuric acid are precisely metered into the reaction system. Accurate dosing is the first critical step in controlling the final product's composition.

Reaction & Synthesis: The materials are dissolved and reacted under controlled conditions to form potassium sulfate (K₂SO₄). This stage requires precise temperature and pH management to maximize conversion efficiency and purity.

Crystallization & Granulation: The SOP solution is cooled and crystallized. The crystals are then formed into strong, uniform granules using a Double Roller granulator. This step is vital for achieving the correct particle size (2-10mm) and physical strength.

Drying & Cooling: The damp granules are gently dried using a low-temperature Rotary Dryer to achieve the optimal moisture content (typically below 1.0%), which is essential for storage stability and preventing caking. A subsequent rotary cooler stabilizes the granules.

Screening & Packaging: Oversized and undersized particles are screened out using rotary screener and recycled, ensuring only on-specification Low Salt Index SOP Fertilizer proceeds to the final stage. The finished product is then packaged in suitable, labeled bags.

5. Ensuring Quality: Control, Standards, and Best Practices

Producing a premium fertilizer demands a relentless focus on quality. Adherence to standards like the Fertilizer Industry Assurance Scheme (FIAS) provides a strong framework. Key control points for a Low Salt Index SOP Fertilizer line include:

Nutrient & Impurity Analysis: Regular laboratory testing is mandatory to verify K₂O and S content and confirm the absence of excessive chlorides or other impurities. This directly validates the low salt index claim.

Physical Quality Checks: Routine tests for granule crushing strength (≥28N is a common benchmark), moisture content, and particle size distribution ensure the product has excellent handling and application properties.

Process Parameter Monitoring: Continuous tracking of reactor conditions, dryer temperatures, and granulator settings is necessary. As industry experts note, stable granulation conditions—often requiring dryer outlet temperatures above 85°C for high-potassium fertilizers—are key to consistent quality.

Documentation & Traceability: Comprehensive records for each batch, from raw material lots to finished product storage, ensure full traceability and facilitate continuous process improvement.

6. Conclusion: Investing in Specialized Production

The dedicated line built with LANE Heavy Industry's machinery boasts remarkable advantages. It is an investment in the future of sustainable agriculture. By focusing on a single premium product, manufacturers can optimize their processes, ensure unparalleled consistency, and build a strong brand in a specialized market. the automated production of LANE production line reduces manual intervention, improving efficiency and avoiding cross-contamination that affects salt index.

7. Frequently Asked Questions (FAQ)

Q1: What exactly does "Low Salt Index" mean for a fertilizer?

A1: The salt index measures a fertilizer's potential to increase soil solution salinity. A Low Salt Index SOP Fertilizer has a much lower potential to burn seeds or harm seedling roots compared to common fertilizers like potassium chloride (MOP). This makes it safer for sensitive crops and for use in saline or dryland soils.

Q2: Can I use a standard NPK compound fertilizer line to produce Low Salt Index SOP?

A2: While possible with major modifications, it is not optimal. Dedicated lines are superior because they are designed for the specific chemical reaction (producing K₂SO₄), purity requirements, and granulation characteristics of SOP. Using a general line risks contamination and inconsistent product quality.

Q3: What are the most critical quality control tests for Low Salt Index SOP Fertilizer?

A3: The most critical tests are: 1) Chemical analysis for K₂O and Sulfur content and chloride impurities; 2) Physical tests for granule hardness (anti-crushing strength) and moisture content; and 3) Particle size screening. Together, these ensure both the agronomic efficacy and mechanical reliability of the fertilizer.

Q4: Why is low-temperature drying important in the production process?

A4: Low-temperature drying, as implemented in lines like LANE's, gently removes moisture without damaging the granule structure or causing nutrient degradation. High heat can lead to hard, poorly soluble granules or even chemical breakdown, compromising the quality of the Low Salt Index SOP Fertilizer.

Q5: Is producing Low Salt Index SOP environmentally friendly?

A5: Compared to many fertilizer processes, modern SOP production can be designed with strong environmental credentials. Leading technologies emphasize processes with high potassium recovery rates, recycle intermediate streams, and are designed to be environmentally benign with minimal effluent, aligning with sustainable production goals.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments