Vermicomposting Integration with Production Lines for Large-Scale Organic Fertilizer Manufacturing

- Efat Elahi

- Sep 4, 2025

- 4 min read

The Role of Vermicomposting in Modern Agriculture

With the increasing concern about soil health and sustainable agriculture, vermicomposting has become one of the most effective methods for recycling organic waste into nutrient-rich fertilizers. Vermicomposting uses earthworms to break down organic matter into substances similar to humus, namely vermicompost, which is very beneficial for plant growth.

Traditional vermicomposting is on a small scale, while industrial agriculture requires a larger scale and more systematic approach. This is where vermicomposting integration with production lines comes in—combining natural decomposition with modern machinery to achieve efficiency, scalability, and consistent fertilizer quality.

What Is Vermicomposting Integration with Production Lines?

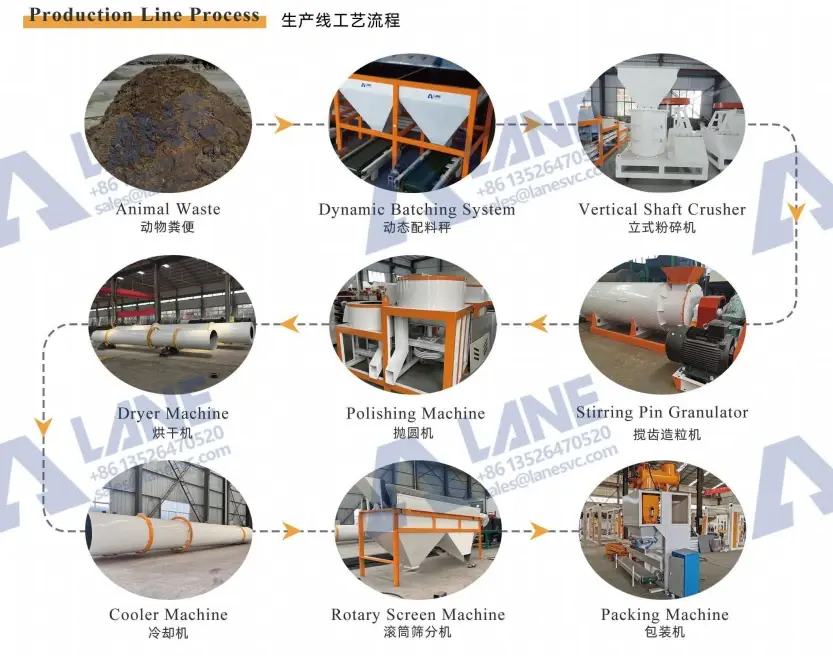

Vermicomposting integration with production lines refers to the process of embedding worm-based composting units into a structured fertilizer production system. Instead of treating vermicomposting as a stand-alone process, it is connected with equipment for crushing, mixing, granulating, drying, and packaging.

This integration creates a continuous flow:

Organic waste is pretreated and prepared.

Worms convert it into nutrient-rich vermicompost.

The material is further processed into granules or liquid fertilizer through production line machinery.

The result is a high-value organic fertilizer that combines the biological richness of vermicompost with the uniformity and market readiness provided by advanced equipment.

Key Steps in the Process

Raw Material Preparation

Organic residues such as crop straw, animal manure, and food waste are collected.

Using crushing machines and mixers, materials are broken down and balanced for optimal worm digestion.

Vermicomposting Units

Earthworms are introduced to feed on the pretreated materials.

Vermicast is harvested regularly, rich in humic acids, beneficial microbes, and plant nutrients.

Separation and Screening

Using rotary screeners, worms are separated from vermicast. Worms are recycled back into the composting unit, while the vermicast moves to further processing.

Granulation (Optional)

Vermicast can be granulated with stirring pin granulators or double roller granulators to produce uniform particles suitable for commercial distribution.

Drying and Cooling

If moisture content is high, rotary drum dryers and coolers bring the granules to a stable condition, ensuring long shelf life.

Final Packaging

With automatic packing machines, vermicompost fertilizer is bagged or bottled for sale in local or export markets.

Advantages of Vermicomposting Integration with Production Lines

Nutrient-Rich Fertilizer: Vermicast contains bioavailable nutrients, enzymes, and beneficial microbes that surpass conventional compost.

Scalability: Integration allows vermicomposting to expand from small farms to industrial-scale fertilizer production.

Higher Market Value: Processed vermicompost granules are easier to store, transport, and sell, compared to raw castings.

Environmental Benefits: Reduces organic waste, cuts landfill loads, and recycles farm residues into valuable resources.

Consistency and Efficiency: By combining biological processes with machinery, fertilizer quality remains uniform and production becomes continuous.

Case Example 1: India’s Organic Farming Cooperatives

In India, vermicomposting has long been practiced at the farm level. A cooperative of farmers integrated vermicomposting units with a full organic fertilizer production line. By doing so, they:

Increased fertilizer output threefold.

Produced granulated vermicompost with higher market demand.

Reduced reliance on synthetic fertilizers while improving crop yields.

Case Example 2: Thailand’s Agro-Industries

In Thailand, food processing industries adopted vermicomposting integration with production lines to manage fruit and vegetable residues. The vermicast was processed using granulation and drying equipment, resulting in a stable organic fertilizer exported to neighboring countries. This approach turned waste disposal costs into new revenue streams.

LANE’s Contribution to Vermicomposting Integration

LANE offers tailored solutions for vermicomposting integration with production lines, ensuring a smooth connection between worm-based composting and industrial-scale fertilizer equipment.

Preprocessing Machines: Crushers and mixers prepare raw materials for efficient worm digestion.

Separation Systems: Screens and sorters efficiently recover worms and separate vermicast.

Granulation Options: Multiple granulator types to suit different fertilizer forms.

Drying & Cooling Equipment: Ensures product stability and storage safety.

Turnkey Services: From design to installation, operator training, and after-sales support, LANE ensures complete project delivery.

With global experience in organic fertilizer equipment, LANE enables farms, cooperatives, and industries to modernize vermicomposting and transform it into profitable fertilizer production.

Frequently Asked Questions

Q1: What waste materials are suitable for vermicomposting?

Crop residues, animal manure, and food waste are all suitable, provided they are pretreated for worm consumption.

Q2: Can vermicomposting be combined with chemical fertilizers?

Yes, vermicompost granules can be used alone or blended with other fertilizers for balanced nutrient supply.

Q3: How long does vermicomposting take?

Typically 30–60 days, depending on the raw materials, worm species, and environmental conditions.

Q4: Why integrate vermicomposting with production lines?

Integration improves efficiency, consistency, and scalability, making the process suitable for commercial production.

The integration of vermicomposting with production lines represents a significant step forward for sustainable agriculture. By combining the natural efficiency of earthworms with advanced equipment such as crushers, mixers, granulators, and packaging systems, farmers and enterprises can achieve reliable large-scale fertilizer production. This method not only reduces waste but also produces stable, organic fertilizers that can be immediately put into the market, thereby enhancing soil fertility and crop yields.

Looking to the future, the integration of earthworm composting and production lines will play an increasingly important role in the global food system. It combines traditional ecological methods with modern engineering technology, making the production of organic fertilizers more efficient, economical and environmentally friendly. With the support of experienced solution providers like LANE, agricultural enterprises can convert organic residues into valuable resources, thereby enhancing farm productivity and ecological balance.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments