Unlocking the Power of Chicken Manure Fertilizer

- Efat Elahi

- Oct 22, 2025

- 4 min read

Chicken manure fertilizer is one of the most valuable organic fertilizers available today, offering a sustainable solution for improving soil health and boosting crop yields. As global agriculture moves toward eco-friendly and cost-effective practices, more farmers and fertilizer producers are turning poultry waste into high-quality organic fertilizer.

Why Chicken Manure Fertilizer Matters

Poultry farming produces a large amount of manure every year, which, if left untreated, can cause odor and environmental pollution. However, when properly processed, chicken manure fertilizer becomes a nutrient-rich product containing nitrogen, phosphorus, potassium, and organic matter, essential for plant growth.

Compared with chemical fertilizers, chicken manure fertilizer releases nutrients slowly, improving soil structure and enhancing microbial activity. It’s an ideal choice for vegetables, fruit trees, grains, and cash crops.

Nutrient Composition of Chicken Manure Fertilizer

Nutrient | Average Content | Function |

Nitrogen (N) | 1.5–2.0% | Promotes leafy growth |

Phosphorus (P₂O₅) | 1.0–1.8% | Supports root development |

Potassium (K₂O) | 0.5–1.0% | Enhances disease resistance |

Organic Matter | 25–35% | Improves soil structure |

This balanced nutrient composition helps plants grow stronger and more resistant to drought and disease, while improving the soil’s water retention and aeration.

How Chicken Manure Fertilizer Is Produced

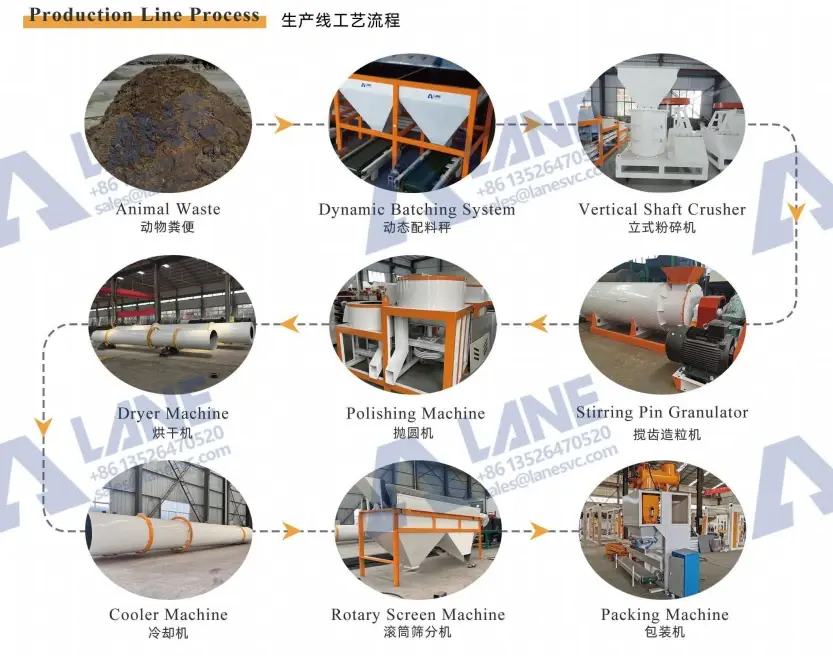

The production of chicken manure fertilizer involves several key stages that transform raw poultry waste into high-quality organic fertilizer granules. Here’s a step-by-step overview of the process and the main equipment involved:

1. Raw Material Collection

Fresh animal waste, mainly chicken manure, is gathered from poultry farms. It may be mixed with straw, rice husk, or sawdust to adjust the carbon-nitrogen ratio and moisture content.

2. Composting Process

Before entering the production line, the manure is composted using equipment such as a crawler type compost turner or wheel type compost turner. This process promotes aerobic fermentation, kills harmful bacteria and pathogens, and converts waste into stable organic matter.

3. Dynamic Batching System

After composting, the material is fed into the dynamic batching system, which automatically measures and mixes different raw materials like humic acid, bone meal, or additional organic additives according to the required formula.

4. Crushing Process

Lumpy composted material is then sent to a vertical shaft crusher. This machine breaks down larger clumps to ensure uniform particle size, improving the quality of the granulation process.

5. Granulation Process

The fine powder mixture enters the stirring pin granulator, where it is shaped into granules under the action of mechanical stirring and moisture. The result is uniform, round fertilizer granules.

6. Drying and Cooling

The newly formed granules contain moisture and are transferred to the dryer machine to remove excess water. Next, they pass through the cooler machine to reduce temperature and prevent clumping during storage.

7. Screening and Polishing

Granules are screened using a rotary screen machine to separate fine or oversized particles, which are returned for re-granulation. Qualified granules then go through the Polishing Machine for a smooth and uniform surface.

8. Final Packaging

Finally, the finished chicken manure organic fertilizer is packed by the Packing Machine into 25kg or 50kg bags, ready for transport or sale.

Benefits of Chicken Manure Fertilizer

Eco-Friendly Solution: Reduces pollution and turns poultry waste into valuable resources.

Improves Soil Health: Increases organic matter, beneficial microbes, and soil fertility.

Cost-Effective: Lower production cost compared to synthetic fertilizers.

Long-Term Benefits: Slow nutrient release helps maintain soil quality over time.

Applications in Modern Agriculture

Chicken manure fertilizer is widely used in organic farming systems for crops such as:

Vegetables (tomatoes, peppers, lettuce)

Rice and maize

Fruit trees (mango, citrus, apple)

Coffee and tea plantations

In countries like Indonesia, India, Kenya, and the Philippines, where sustainable farming is growing rapidly, chicken manure fertilizer production lines have become a profitable and environmentally friendly investment.

LANE’s Experience in Chicken Manure Fertilizer Production Equipment

Henan LANE Heavy Industry Co., Ltd. has rich experience in designing and manufacturing complete chicken manure fertilizer production lines, from compost turners and mixers to granulators and packaging machines.LANE’s equipment offers:

High automation and efficiency

Durable construction and low maintenance

Customizable capacity (from 1–20 tons/hour)

Professional installation and after-sales service

With successful projects in Southeast Asia and Africa, LANE helps clients transform poultry waste into high-quality chicken manure organic fertilizer efficiently and economically.

Case Example: Poultry Waste Recycling Project in Kenya

A medium-scale poultry farm in Kenya partnered with LANE to establish a 5 tons/hour chicken manure fertilizer plant.Within three months of operation, the farm reduced waste disposal costs by 40% and increased income by selling organic fertilizer locally. The project not only improved farm sustainability but also created new jobs in the community.

Challenges and Future Trends

Although chicken manure fertilizer production offers great potential, challenges include managing odor, ensuring proper composting, and maintaining consistent nutrient quality.Future trends point toward automation, smart fermentation monitoring, and liquid fertilizer production from poultry waste, enhancing both efficiency and environmental performance.

Chicken manure fertilizer is more than just recycled waste — it’s a sustainable resource for the future of agriculture. With proper processing and modern equipment, poultry waste can be turned into nutrient-rich organic fertilizer that boosts yields, restores soil health, and supports green farming worldwide.

LANE Heavy Industry continues to assist global clients in creating efficient organic fertilizer plants that turn environmental challenges into agricultural opportunities.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments