Powering Growth with Precision: NPK Liquid Fertilizer Production Line Unveiled

- Efat Elahi

- Aug 7, 2025

- 4 min read

Updated: Aug 7, 2025

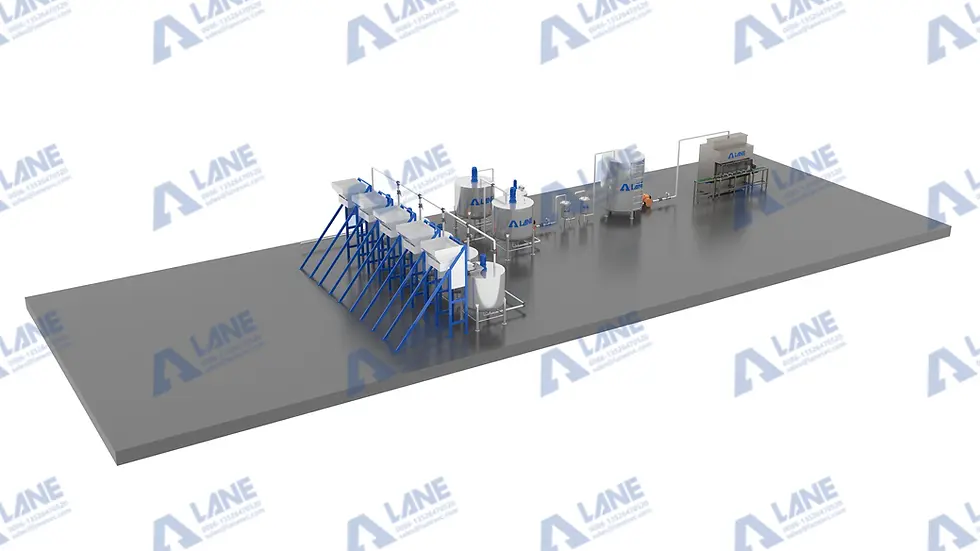

If you're considering expanding into liquid fertilizers, NPK liquid fertilizer production line is fast becoming the go-to solution for modern, efficient, and eco-conscious operations. Whether you’re aiming to serve local growers or break into export markets, understanding how a robust, customizable production line works—and why LANE’s equipment leads the industry—can turn a bold vision into a thriving reality.

Why Liquid NPK Fertilizers Are Game-Changers

NPK—nitrogen, phosphorus, and potassium—is the backbone of balanced plant nutrition. When formulated into liquid fertilizer, NPK is absorbed more quickly, and application is more convenient (especially through foliar spraying or irrigation fertilization), and it can precisely fertilize according to the crop's needs. Compared with granular fertilizer, liquid NPK enables rapid field fertilization and is highly suitable for greenhouse growers or specialized crop growers who emphasize control and consistency.

Personal Experience: From Skeptic to Convert

I remember visiting a wheat grower friend last year who had been using granular fertilizer exclusively. He was skeptical when I suggested liquid NPK solutions. Within two weeks of trialing a batch from a local LANE-equipped plant, he noticed greener leaves and better tillering in his fields. That first-hand success explored what a properly implemented NPK liquid fertilizer production line can do for yield quality—and convinced him to invest in a small on-site production pilot soon after.

Components of an NPK Liquid Fertilizer Production Line

Constructing an efficient NPK liquid fertilizer production line involves multiple phases, each with its own equipment and quality controls:

1. Raw Material Handling & Dissolution

Precise dosing of nutrient salts—like urea (N), ammonium phosphate (P), and potassium chloride or sulfate (K)—is done using LANE’s stainless-steel dissolution tanks equipped with agitators. This ensures full solubility without hotspots or over-saturation.

2. Mixing & Stabilization

After dissolution, the solution will enter a high-speed Ryan homogenizer. Here, additives such as chelating agents or micronutrients are mixed together in a stainless steel mixing tank to achieve a uniform concentration. pH and EC (electrical conductivity) are monitored throughout to match crop requirements.

3. Filtration and Purification

To ensure nozzle-friendly, impurity-free liquid, the solution passes through a fine dual filtration system—an essential component in a reliable NPK liquid fertilizer production line.

4. Storage & Stabilization Tanks

Once filtered, the fertilizer is housed in stainless steel storage tanks. Optional UV stabilizers or corrosion inhibitors may be added depending on storage requirements.

5. Filling & Packaging

Whether delivering in bulk IBCs or in 1–5L jugs, LANE’s automatic liquid filling and capping systems ensure precise dosing and clean, tamper-resistant sealing.

Why LANE Makes the Difference

LANE’s prowess in NPK liquid fertilizer production line systems stems from its pivotal strengths:

Scalable Design: Systems range from 500L to 50,000L per shift, catering to small retailers and industrial manufacturers alike.

Quality Control: Digital dashboards allow real-time tracking of NPK ratios, pH, and stability—ensuring consistency batch after batch.

After-Sales Support: We go beyond equipment—offering commissioning assistance, operator training, and remote diagnostics to minimize downtime.

Certifications: With CE and ISO certifications, our equipment meets global standards, simplifying export compliance.

Applications Across Agriculture: How NPK Liquid Fertilizer Fits Every Field

One of the greatest advantages of investing in a NPK liquid fertilizer production line is its wide application in the agricultural field. From small-scale vegetable growers to large commercial grain producers, liquid NPK formulations are no longer just a trend but a necessity in modern agriculture.

Tree crops and vineyards

Perennial crops require a continuous and balanced supply of nutrients throughout the growing season. The liquid NPK applied through drip irrigation systems can provide precise nutrients without disturbing the soil. Growers have reported better flowering effects, higher fruit set rates, and more developed root systems.

Grain and row-cropped crops

Farmers growing wheat, corn, and soybeans are increasingly incorporating liquid NPK into their planting plans. When combined with intelligent fertilization tools such as circular sprinkler machines or boom sprayers, liquid NPK can ensure efficient coverage and faster absorption, especially during the critical early growth stages.

Organic and sustainable farms

Although traditional NPK sources may not always meet organic certification requirements, LANE can help producers customize NPK liquid fertilizer production lines to use certified organic mineral inputs. This opens the door for sustainable growers to expand their operations without compromising their value.

Whether it's a 5-acre strawberry farm or a 5,000-acre plantation, the liquid NPK fertilizers produced by the LANE system can meet the flexibility, precision, and consistency requirements of today's farmers.

A Smart Harvest Begins with Liquid Precision

In the ever-evolving world of modern agriculture, precision isn’t just a luxury—it’s a necessity. The NPK liquid fertilizer production line empowers growers to deliver nutrients exactly when and where they’re needed, maximizing both yield and resource efficiency. Whether you're a large-scale fertilizer manufacturer or a regional cooperative looking to boost local productivity and exports, liquid NPK represents a future-forward solution.With LANE’s custom-engineered systems, reliable technical support, and international project experience, setting up your own production line is more achievable than ever.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments