Organic Fertilizer Line from Cow Manure: Sustainable Processing Solutions by LANE

- Efat Elahi

- Oct 11, 2025

- 5 min read

Organic fertilizer line from cow manure is an innovative and environmentally friendly technology that converts livestock waste into high-value organic fertilizer. With the increasing global demand for sustainable agricultural practices and the need to reduce pollution from animal husbandry, organic fertilizer production has become an essential part of modern circular agriculture.

As a leading global manufacturer of fertilizer production equipment, LANE provides turnkey solutions for building complete organic fertilizer lines from cow manure. Through advanced design, precision manufacturing, and strong engineering experience, LANE helps clients worldwide transform waste into wealth—producing high-quality organic fertilizer efficiently and safely.

Turning Waste into Agricultural Value

Cow manure is rich in nitrogen, phosphorus, potassium, and organic matter, making it a valuable natural fertilizer source. However, untreated manure can release methane, ammonia, and other pollutants into the environment. An organic fertilizer production line from cow manure provides a sustainable solution by processing raw waste into stable, nutrient-balanced fertilizer suitable for various crops and soils.

The key benefits of using LANE’s system include:

Reduction of livestock waste pollution

Production of high-quality, odor-free organic fertilizer

Recovery of valuable nutrients for agricultural use

Improved soil fertility and structure

Compliance with environmental regulations

By combining LANE’s advanced machinery and intelligent process design, clients can achieve a zero-waste cycle while improving productivity and environmental sustainability.

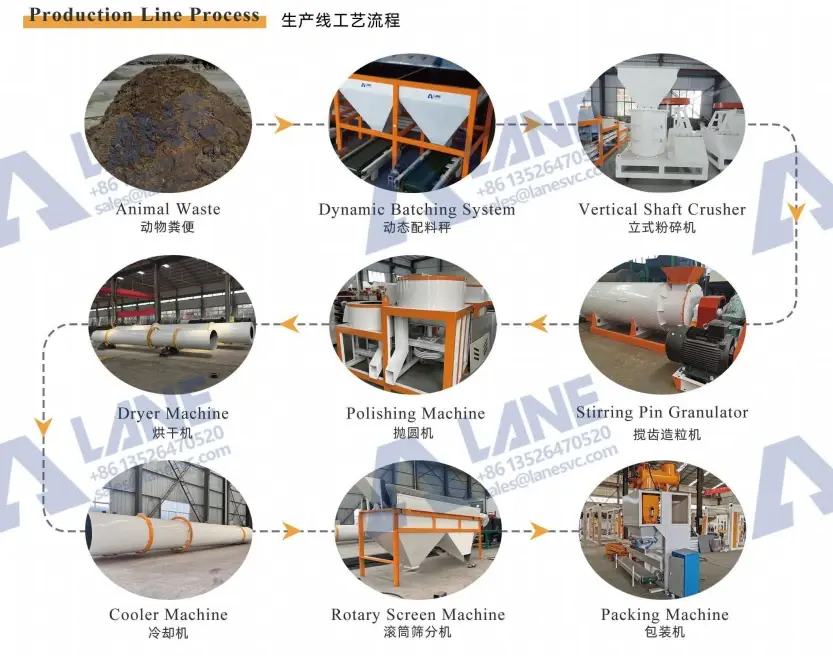

The Complete Production Process of Organic Fertilizer from Cow Manure

The production process involves several stages, each supported by specialized LANE equipment to ensure efficiency and quality. Below is a complete process overview.

Stage | Equipment | Function Description |

1 | Animal Waste Collection | Cow manure is collected and stored for processing. |

2 | Dynamic Batching System | Automatically weighs and mixes raw materials, ensuring accurate nutrient proportions. |

3 | Vertical Shaft Crusher | Crushes large pieces and lumps of manure to achieve uniform particle size. |

4 | Stirring Pin Granulator | Mixes and granulates material into fine organic fertilizer pellets. |

5 | Polishing Machine | Refines pellet shape for uniformity and smooth appearance. |

6 | Dryer Machine | Removes moisture to stabilize fertilizer and extend storage life. |

7 | Cooler Machine | Reduces temperature of dried granules to prevent caking. |

8 | Rotary Screen Machine | Classifies granules by size, separating fine and oversized particles. |

9 | Packing Machine | Automatically packages the final fertilizer into bags for sale or distribution. |

Each stage is fully automated and controlled by LANE’s advanced PLC system to guarantee efficiency, consistency, and safety.

Key Equipment in LANE’s Organic Fertilizer Line from Cow Manure

Dynamic Batching System

This system ensures precise proportioning of cow manure and auxiliary materials such as crop residues or humic substances. It features electronic weighing systems and automated feeders, providing consistent mixture ratios that enhance fertilizer quality.

Vertical Shaft Crusher

Designed to crush and refine cow manure after preliminary drying or composting, the vertical shaft crusher breaks down larger particles, improving homogeneity for granulation.

This granulator is the heart of the process. It mixes organic material under controlled moisture conditions, forming small, uniform granules through high-speed mechanical stirring and collision. It supports moisture content of 20–40%, ideal for organic fertilizer granulation.

The polishing machine smooths and strengthens granules, giving them an attractive appearance and improved durability. It helps reduce dust and ensures consistent particle size.

The dryer machine removes excess water, reducing the final moisture content to below 10%. The cooler machine follows immediately, ensuring the product is stable and non-sticky, which is essential for packaging and storage.

This machine separates qualified granules from undersized and oversized ones. Recycled material is returned to the granulator, ensuring zero waste during production.

Automatic Packing Machine

The packing system uses electronic scales and sealing mechanisms to fill bags ranging from 25 to 50 kg, ensuring high precision and efficiency. It is suitable for large-scale industrial packaging.

Advantages of LANE’s Organic Fertilizer Production Solutions

LANE’s organic fertilizer line from cow manure is engineered for performance, durability, and sustainability. Its advantages include:

1. Complete Turnkey Solutions

LANE provides full-service support—from design and equipment manufacturing to on-site installation and operator training. Clients receive an integrated production system ready for operation.

2. Customized Design

Each production line is customized based on raw material composition, production capacity, and desired fertilizer type. LANE can design both powder and granular fertilizer systems.

3. Energy Efficiency and Automation

Advanced automation reduces manual labor while improving accuracy. The system incorporates intelligent temperature and moisture control for stable operation and energy savings.

4. Environmentally Friendly Process

The line minimizes odor and emissions through sealed systems and optimized drying technologies, ensuring compliance with international environmental standards.

5. Global Technical Service

LANE’s international service network offers installation, maintenance, and remote technical support, ensuring continuous and reliable production worldwide.

Case Example: Cow Manure Fertilizer Project in South America

A large dairy farm in South America partnered with LANE to install a 5,000-ton-per-year organic fertilizer line from cow manure. The goal was to turn daily waste into marketable fertilizer while reducing environmental impact.

Project Highlights:

Raw Material: Fresh cow manure from 3,000 cattle

Final Product: Granular organic fertilizer with NPK 4-3-3 composition

Equipment Supplied: Complete line including crusher, granulator, dryer, and packaging system

Energy Savings: 22% reduction in electricity consumption

Output: Over 400 tons of finished organic fertilizer per month

This project successfully achieved zero-waste production while generating additional revenue for the farm.

Common Formulations and Output Options

LANE’s organic fertilizer lines can produce various formulations according to customer needs:

Pure organic fertilizer from cow manure compost

Bio-organic fertilizer with added microorganisms

Compound organic fertilizer blended with NPK or trace elements

Pellet or powder forms for flexible market use

Each formulation can be adjusted to suit local soil conditions, crop requirements, and regional regulations.

Frequently Asked Questions (FAQ)

Q1: What is the moisture requirement for cow manure before processing?

Typically, cow manure should have 30–40% moisture for optimal granulation. LANE offers pre-treatment drying systems if the moisture is too high.

Q2: How long does it take to install the entire production line?

Depending on the scale, installation and commissioning usually take 30–60 days.

Q3: Can the line handle other animal waste materials?

Yes. The system can process chicken manure, pig manure, and other organic wastes with minor configuration adjustments.

Q4: What is the expected lifespan of the equipment?

LANE’s machines are made of high-grade stainless steel and carbon steel with anti-corrosion coating, providing over 10 years of service life under normal operation.

Q5: Does LANE provide after-sales support?

Yes. LANE provides global technical support, spare parts supply, and online troubleshooting services.

The Future of Organic Fertilizer from Cow Manure

With the growing emphasis on sustainable agriculture and environmental protection, organic fertilizer line from cow manure represents the future of waste recycling and nutrient recovery. It not only addresses manure disposal issues but also creates a profitable business model for farms and agricultural enterprises.

LANE continues to innovate and improve organic fertilizer production technologies, ensuring higher productivity, lower energy consumption, and consistent quality for customers worldwide.

LANE is committed to delivering advanced, reliable, and eco-friendly fertilizer production solutions. Whether for small farms or industrial operations, LANE’s organic fertilizer line from cow manure enables efficient resource utilization and long-term sustainability.

By choosing LANE, you partner with a company that combines global expertise, engineering innovation, and customer-focused service to help you build a greener and more profitable agricultural future.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments