Organic Farming’s Secret Weapon: Turning Animal Manure into Fertilizer

- Efat Elahi

- Aug 5, 2025

- 3 min read

Updated: Aug 18, 2025

Turning animal manure into fertilizer is one of the most practical and eco-friendly solutions in modern agriculture. Instead of treating manure as waste, farms and agribusinesses can transform it into a valuable, nutrient-rich product that boosts crop yields, improves soil health, and opens up new revenue opportunities. With growing demand for organic farming and sustainable practices, more producers are investing in professional manure-to-fertilizer production systems. LANE provides turnkey solutions for turning animal manure into fertilizer, offering full-scale production lines, technical expertise, and global installation services to help clients turn waste into profit.

Why Turning Animal Manure into Fertilizer Matters

Around the world, the livestock industry produces hundreds of millions of tons of manure every year. If not managed properly, this manure can cause environmental pollution, greenhouse gas emissions and groundwater contamination.By turning animal manure into fertilizer, farmers can:

Recycle nutrients back into the soil.

Reduce dependency on expensive chemical fertilizers.

Comply with environmental regulations and avoid waste disposal costs.

Generate additional income by selling high-quality organic fertilizer.

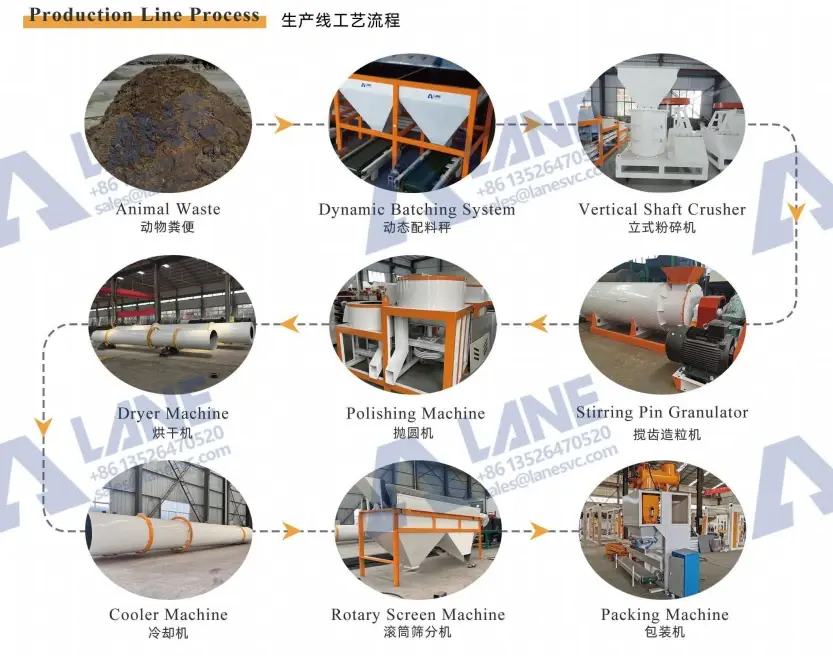

How the Process Works – Step-by-Step

The turning animal manure into fertilizer process involves several carefully designed stages to ensure a clean, pathogen-free, and nutrient-rich final product.

Raw Material Collection & Pre-Processing: Livestock manure is collected and may be mixed with crop residues or bedding materials to balance carbon and nitrogen ratios.

Composting & Fermentation: Using equipment such as the LANE hydraulic crawler type compost turner, manure piles are aerated and mixed to accelerate microbial activity. This process eliminates pathogens and reduces odor.

Crushing & Mixing: After composting, the semi-cured material is processed through a semi-wet material crusher for uniform particle size. It is then blended with mineral additives in a horizontal mixer for balanced nutrient content.

Granulation: The blended material is shaped into uniform granules using equipment such as the LANE double roller granulator or stirring pin granulator. Granules are easier to handle, store, and apply.

Drying & Cooling: Moisture is reduced in a rotary drum dryer, followed by a cooling machine to improve storage stability.

Screening & Packaging: A rotary screener ensures consistent granule size. Finally, the fertilizer is bagged using a fully automatic packaging system for sale or farm use.

Applications – Where This Fertilizer Is Used

Turning animal manure into fertilizer can produce nutrient-rich organic products, which are widely used in various fields of agriculture to promote sustainable growth of crops and increase yields. Its applications are extensive, whether for small family farms or large commercial operations, and it is the preferred choice in both cases.

Field Crops – Commonly applied to large-scale grain production such as wheat, corn, rice, and soybeans. It helps restore depleted soils, increases organic matter, and improves water retention, leading to healthier plants and higher harvest volumes.

Vegetable and Fruit Production – Ideal for tomatoes, peppers, grapes, apples, and other high-value crops. Farmers have reported improved flavor, longer shelf life, and reduced chemical residue when switching to organic fertilizer derived from animal manure.

Pasture and Forage Crops – Boosts the nutritional value of feed for dairy and beef cattle, enhancing animal health and productivity. It also supports healthier grazing lands, ensuring long-term sustainability for livestock operations.

Greenhouse Farming – Perfect for controlled environments, as it delivers slow-release nutrients without causing chemical burn to delicate seedlings. Its pathogen-free nature after composting ensures safe usage in enclosed spaces.

Land Restoration – Used in soil rehabilitation projects to restore degraded lands, reduce erosion, and re-establish vegetation. Many governments and environmental organizations encourage turning animal manure into fertilizer as part of eco-restoration programs.

Real-World Case Studies

Case Study 1 – Organic Vegetable Farm in the Netherlands

A medium-sized vegetable farm invested in a LANE turning animal manure into fertilizer production line to improve soil health and reduce dependence on synthetic inputs. Within one season, soil organic matter increased by 28%, boosting nutrient retention and microbial activity. Yields improved by 15%, and the farm began selling surplus organic fertilizer locally, generating an additional €45,000/year in revenue. The farmer also reported better vegetable taste and customer satisfaction.

Case Study 2 – Dairy Cooperative in South America

A dairy farmers’ cooperative faced high manure disposal costs and nutrient runoff issues. They adopted a LANE full-process manure-to-fertilizer system, including compost turners, crushers, mixers, granulators, dryers, and automated packaging equipment. The cooperative reduced manure disposal costs by 90% and began exporting high-quality organic fertilizer to neighboring regions. This new revenue stream brought in an extra $150,000/year, while also improving pasture health for their cattle herds.

Turning animal manure into fertilizer is a proven strategy that benefits farmers, the environment, and the economy. It reduces waste, improves soil health, and increases farm profitability. With LANE’s advanced equipment, global installation support, and proven track record, farms and agribusinesses can easily transform manure into a valuable product—turning waste into profit and building a greener, more sustainable agricultural future.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments