Optimizing Crop Growth with Foliar Spray Liquid Fertilizer Production Equipment

- Efat Elahi

- Sep 2, 2025

- 4 min read

The agricultural industry is constantly evolving, with new techniques and technologies emerging to address the growing demand for sustainable, efficient farming practices. One of the most innovative approaches to enhancing crop nutrition is foliar spray liquid fertilizer, which delivers essential nutrients directly to the leaves of plants. By providing nutrients in this way, foliar fertilizers can lead to faster absorption, improved crop yield, and enhanced plant health. The key to maximizing the benefits of foliar feeding lies in the foliar spray liquid fertilizer production equipment used to create these highly effective products.

What is Foliar Spray Liquid Fertilizer?

Foliar Spray Liquid Fertilizer is a method of applying liquid fertilizer directly to the leaves of plants rather than to the soil. The main advantage of this method is that plants can quickly absorb nutrients through the stomata (tiny pores on the surface of the leaves), which is faster and more efficient than traditional soil fertilizers.

These fertilizers contain essential nutrients such as nitrogen (N), phosphorus (P), potassium (K), and other trace elements that are crucial for plant health and growth. Leaf spraying is particularly effective in quickly addressing nutrient deficiency problems, especially in cases where soil conditions are poor or nutrient absorption is slow, resulting in poor effectiveness from soil application.

Benefits of Foliar Spray Liquid Fertilizer

Faster Nutrient Absorption: Foliar fertilizers are absorbed much faster than soil-based fertilizers because they bypass the plant’s root system. This allows the nutrients to reach the plant quickly, making them an excellent option for correcting nutrient deficiencies during critical growth stages.

Improved Crop Yield: By providing essential nutrients directly to the leaves, foliar fertilizers ensure that plants have the right nutrients at the right time. This results in healthier plants, better root development, and ultimately higher crop yields.

Efficient Nutrient Delivery: Foliar spraying allows farmers to apply a precise amount of fertilizer directly where it is needed, reducing the risk of over-fertilization and nutrient runoff. This leads to more efficient use of fertilizers and reduced environmental impact.

Enhanced Plant Health: Foliar spraying can help protect plants from stress caused by environmental factors such as drought, pests, or disease. It strengthens plant defenses and promotes overall plant vigor, reducing the need for pesticides and other chemical interventions.

Reduced Soil Dependency: Foliar fertilization helps reduce reliance on soil-based fertilizers, which can be affected by various factors such as soil pH and texture. This makes foliar spray a valuable tool in areas with poor or contaminated soils.

The Production Process of Foliar Spray Liquid Fertilizers

Creating high-quality foliar spray liquid fertilizers requires a precise and efficient production process. Below is an overview of the general steps involved in producing foliar spray fertilizers, along with the equipment used in each stage.

1. Raw Material Selection

The first step in the production process is selecting the raw materials. These typically include water-soluble fertilizers, micronutrients, and other additives such as surfactants and stabilizers. These ingredients are sourced from reputable suppliers to ensure the quality of the final product.

2. Mixing and Blending

The selected raw materials are mixed together in a stainless steel mixing tank. This stage requires precise control over the amount of each ingredient to ensure that the nutrient ratios are accurate. The stainless steel mixing tank is equipped with a high-efficiency agitator to ensure that the fertilizers are thoroughly dissolved and blended.

3. Filtration

To remove any impurities or solid particles, the mixture is passed through a dual filter system. The dual filter system ensures that the final product is clear and free of any undissolved particles, which could clog the spray nozzles or damage the plants.

4. Quality Control

The mixture undergoes rigorous quality control checks to ensure that the nutrient content, pH, and viscosity are within acceptable ranges. Adjustments are made as necessary to ensure the consistency and effectiveness of the product.

5. Packaging

Once the foliar spray liquid fertilizer has passed all quality control tests, it is transferred to an automatic packing machine. This machine fills the product into bottles, pouches, or other containers, ensuring accurate weights and preventing any contamination during the packaging process.

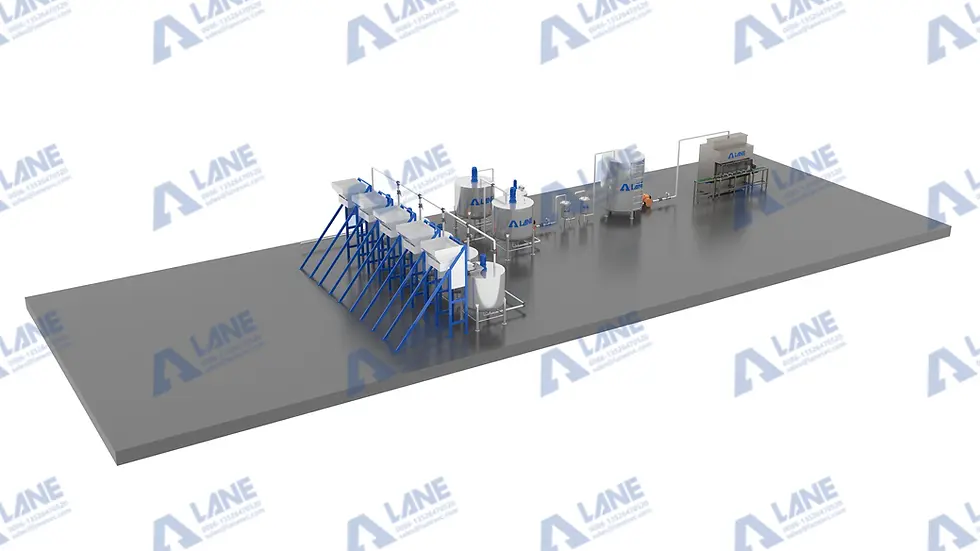

How LANE’s Equipment Optimizes Foliar Spray Production

LANE is at the forefront of agricultural technology, providing state-of-the-art equipment to streamline the production of foliar spray liquid fertilizers. Our systems are designed to improve efficiency, reduce waste, and deliver high-quality products every time.

High-Efficiency Liquid Mixing Tanks

Our stainless steel mixing tanks feature advanced agitators that ensure thorough blending of ingredients, resulting in a uniform mixture that maximizes the effectiveness of the fertilizer.

Dual Filter System

Our dual filter system removes solid particles and impurities, ensuring that the final product is free from any contaminants that could affect plant health or clog spray nozzles.

Automatic Packing Machines

The automatic packing machine from LANE provides a high level of accuracy and efficiency in the packaging process. It minimizes human error, increases production speed, and ensures that each container is filled with the correct amount of fertilizer.

Customizable Fertilizer Production

With LANE’s equipment, the production of foliar spray fertilizers can be tailored to meet specific nutrient requirements, based on the type of crops being grown and the needs of the farmer. Our flexible systems enable the formulation of customized blends to address various plant growth stages and environmental conditions.

Foliar spray liquid fertilizers are revolutionizing the way farmers provide nutrients to their crops. By delivering nutrients directly to the leaves, these fertilizers offer faster absorption, improved crop yields, and enhanced plant health. The production of foliar spray fertilizers requires advanced equipment, and LANE provides state-of-the-art solutions that ensure efficiency and quality throughout the production process. From mixing tanks to automatic packing machines, LANE’s cutting-edge technology helps farmers produce the best possible foliar fertilizers, contributing to healthier crops and more sustainable farming practices.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments