Maximizing Efficiency with an Organic Fertilizer Production Line

- Efat Elahi

- Jul 28, 2025

- 4 min read

Updated: Aug 1, 2025

An organic fertilizer production line is essential for any operation looking to efficiently convert organic waste into valuable, high-quality fertilizers. As the demand for sustainable agricultural solutions continues to rise, an optimized production line can drastically improve both productivity and environmental impact. This blog explores the key components of a well-functioning organic fertilizer production line, the advantages it offers, and how LANE’s customized solutions can help streamline your production process.

What is an Organic Fertilizer Production Line?

An organic fertilizer production line refers to an integrated system designed to convert organic waste into high-quality fertilizers. These materials range from animal feces, food waste and agricultural residues to green waste. The production line consists of multiple stages, each of which is designed to convert raw organic matter into nutrient-rich environmentally friendly fertilizers ready for use in agricultural applications.

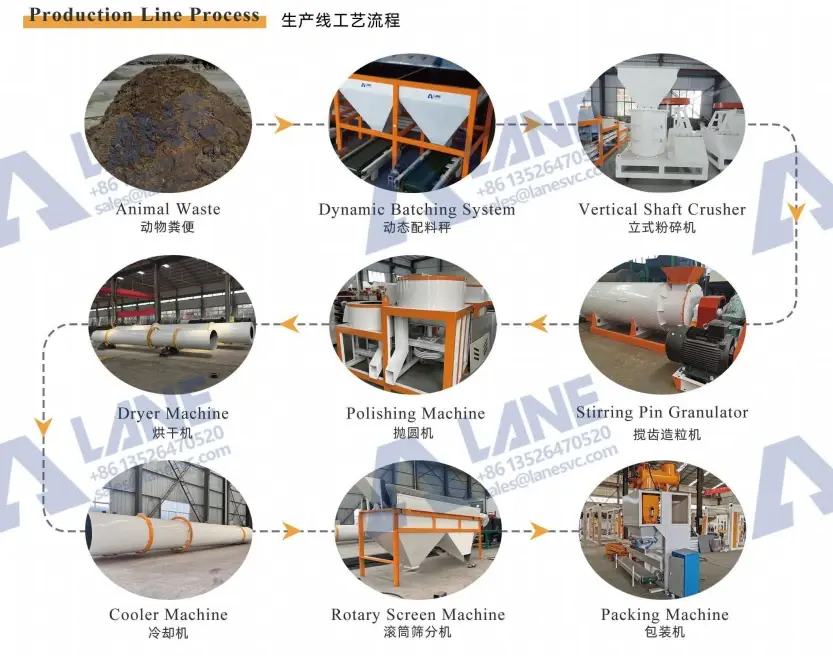

An efficient production line includes:

Fermentation and composting systems

Crushers

Granulation or polishing machines

Drying and cooling systems

Rotary screener

Packaging systems

These stages ensure that the raw materials undergo necessary transformations, turning them into a final product that is both beneficial for the environment and highly effective for plant growth.

Why Choose an Organic Fertilizer Production Line?

The benefits of a well-designed organic fertilizer production line are numerous. Some of the key advantages include:

1. Cost-efficiency

Organic fertilizers usually reduce the need for expensive synthetic fertilizers. A well-designed production line ensures that the original organic waste is converted into valuable fertilizer at a lower cost. This can make your operations more competitive in the market while helping to reduce production costs.

2. Environmental sustainability

The world is increasingly concerned about sustainability, and the use of organic fertilizers is a key part of reducing environmental degradation. Organic fertilizers improve soil health, enhance moisture retention, and reduce the risk of soil erosion. The production process also helps recycle waste and turn it into valuable products.

3. Improve plant productivity

Organic fertilizers are rich in nutrients that enhance soil fertility, promote beneficial microbial activity and encourage healthy root systems. This leads to crop yields and healthier plants, which benefit farmers and the food production industry.

Key Components of an Organic Fertilizer Production Line

An efficient organic fertilizer production line integrates various components designed to work together seamlessly. Here’s a breakdown of the essential stages:

The first step in the production process is the fermentation of the organic material. This process can be carried out in a variety of ways, including aerobic or anaerobic fermentation. Compost turners are used to ensure that the organic waste is turned and decomposed evenly, thus speeding up the decomposition of the material.

At LANE, we provide customized fermentation systems to speed up the fermentation process and ensure that the raw materials are broken down to the optimal consistency, ready for the subsequent stages.

2. Crushers

After fermentation is complete, the organic material needs to be crushed to a fine and uniform consistency. Horizontal semi-wet material crusher or vertical shaft crusher ensures that the product is ready for the mixing and granulation stages. Our advanced crushing technology minimizes energy consumption while maximizing output.

3. Granulation and Polishing Machines

The production line then uses a granulator to form the mixed organic matter into granules or pellets. There are many types of granulators, such as disc granulators or rotary drum granulators. The granulation process ensures that the fertilizer is easy to handle, transport and apply to the soil. Polishing machines are then used to make the granules uniform.

At LANE, we provide custom-set granulators according to different material types and production needs, ensuring that each customer's fertilizer has the right texture and consistency.

4.Drying and Cooling Systems

After granulation, the fertilizer granules must be dried and cooled to stabilize them and prepare them for packaging. Rotary drum dryers and cooling machines from LANE maintain an energy-efficient balance, ensuring that the final product retains its effectiveness while minimizing operational costs.

5.Rotary Screener

When working, the rotary screener starts first, the drum starts to rotate, and the material to be screened is fed into the drum. The drum is usually placed at an angle or horizontally, with screens of different sizes inside. When the drum rotates, the material is lifted to a certain height as the drum rotates, and then falls under the action of gravity.

In this process, smaller particles of material fall into the collection bucket through the screen holes, while larger particles are blocked inside the screen, thereby achieving material classification.

6.Packaging Systems

The final step in the production process is packaging. The finished fertilizer must be safely and efficiently packaged for distribution. Our automatic packaging machines ensure precise dosages and consistent packaging, reducing labor costs and minimizing errors in the packing process.

An organic fertilizer production line is more than just a system; it is an investment in sustainability, cost-effectiveness, and long-term growth. By choosing LANE’s custom equipment and taking advantage of our professional after-sales service, your business will not only produce high-quality fertilizers, but also contribute to the global shift to a sustainable agricultural model.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments