Liquid Fertilizer Mixer: Essential Equipment for Modern Fertilizer Production

- Efat Elahi

- Sep 5, 2025

- 4 min read

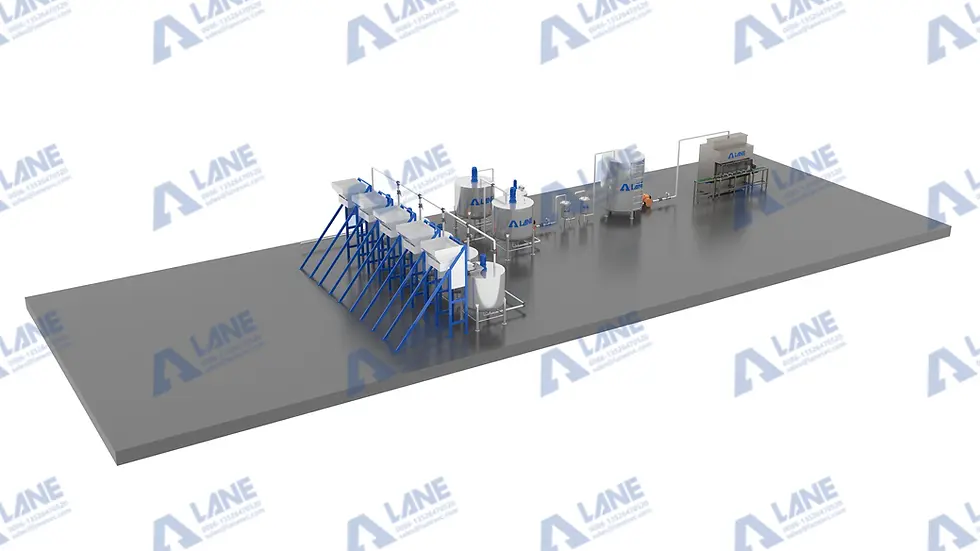

The liquid fertilizer mixer is one of the important equipment for liquid fertilizer production line. Its function is to mix raw materials, additives and water-soluble nutrients into a uniform solution, so as to facilitate efficient storage, transportation and application. Whether it is a small farm, a cooperative or an industrial-scale fertilizer factory, the liquid fertilizer mixer can ensure the consistency and quality of the products.

Modern systems usually incorporate various types of mixers, such as raw material mixing tanks, mixing tanks and additive mixing tanks. These devices work together to ensure that the production formula of liquid fertilizers is precise, the production efficiency is high, and the flexibility is strong.

Why Use a Liquid Fertilizer Mixer?

Uniformity: Prevents nutrient segregation and ensures balanced formulations.

Efficiency: Saves labor and time compared to manual mixing.

Scalability: Suitable for both small-scale and large industrial production.

Versatility: Can handle organic extracts, chemical solutions, and micro-nutrient blends.

Precision: Supports accurate dosing of additives for customized fertilizer recipes.

Without a proper liquid fertilizer mixer, the production process risks inconsistency, sedimentation, and poor crop performance.

Step-by-Step Process with Liquid Fertilizer Mixers

Step 1: Raw Material Preparation

Raw inputs such as urea, ammonium salts, potassium sources, or organic extracts are weighed and delivered into the raw material mixing tank. This tank dissolves and disperses the main ingredients, creating a stable base solution.

Step 2: Bulk Mixing

The solution is transferred to the stainless steel mixing tank, where continuous agitation ensures that solids remain suspended and liquids fully blended. Impellers, paddles, or jet mixers are used depending on viscosity.

Step 3: Additive Integration

Micro-nutrients, stabilizers, pH regulators, or biological additives are added through the additive mixing tank. This ensures that sensitive components are incorporated at the right stage without degradation.

Step 4: Homogenization and Quality Check

After blending, the final liquid fertilizer is tested for pH, nutrient concentration, and stability. Additional adjustments can be made by circulating through the liquid fertilizer mixer system.

Step 5: Storage and Packaging

The finished product is pumped into stainless steel storage tanks or directly into automatic filling systems for bottling, bagging, or bulk containers.

Types of Tanks in a Liquid Fertilizer Mixer System

1. Raw Material Mixing Tank

Used for dissolving and dispersing bulk nutrients such as urea, potassium nitrate, or organic extracts.

Equipped with heating or circulation systems if needed to improve solubility.

Ensures the base solution is stable and free from large undissolved particles.

2. Mixing Tank

Acts as the central blending unit in the liquid fertilizer mixer system.

Provides constant agitation to keep the solution uniform.

Built with corrosion-resistant materials (e.g., stainless steel or lined carbon steel).

May include sensors for temperature, pH, and mixing speed control.

3. Additive Mixing Tank

Designed for precise dosing of trace elements, chelates, or biological additives.

Prevents sensitive ingredients from being exposed to prolonged heat or high shear.

Allows flexible formulation adjustments before the final product is completed.

Together, these three tanks form the complete liquid fertilizer mixer system, ensuring efficiency and accuracy in every batch.

LANE’s Advantages in Liquid Fertilizer Mixer Systems

High-Quality Materials: Tanks are made from stainless steel or food-grade plastics, resistant to corrosion from acidic or alkaline fertilizers.

Custom Designs: Capacity ranges from 500 liters for small farms to over 20,000 liters for industrial plants.

Automation: PLC control systems allow automated dosing, mixing, and monitoring of key parameters.

Energy Efficiency: Optimized impellers and motor systems reduce power consumption.

Global Service: LANE provides turnkey solutions including layout design, installation, training, and after-sales support.

Case Example: India’s Greenhouse Cooperative

A vegetable growers’ cooperative in India adopted a liquid fertilizer mixer system with three tanks. The raw material mixing tank dissolved water-soluble fertilizers, the mixing tank maintained uniform solutions, and the additive mixing tank integrated micronutrients. The system allowed the cooperative to produce customized fertigation solutions, increasing yields by 15% while reducing chemical waste.

Benefits of Using a Liquid Fertilizer Mixer System

Consistent Quality: Every batch meets nutrient specifications.

Flexibility: Easy to adjust formulas for different crops and soils.

Cost Efficiency: Reduces manual labor and errors in mixing.

Scalability: Adaptable to both local farm operations and international fertilizer companies.

Sustainability: Enables recycling of agricultural and industrial byproducts into liquid fertilizers.

Frequently Asked Questions

Q1: What capacity of liquid fertilizer mixer do I need?

Small farms may need 500–1000 L mixers, while industrial plants may require 10,000–20,000 L systems.

Q2: Can organic materials be used?

Yes, the raw material mixing tank can handle organic extracts like fish protein or yeast hydrolysates.

Q3: How are additives protected from degradation?

The additive mixing tank introduces sensitive components at the final stage to avoid heat and high shear damage.

Q4: Are mixers easy to clean?

Yes, most designs include cleaning ports or CIP (clean-in-place) systems for hygiene.

Q5: Can the system be automated?

Yes, LANE offers PLC-based controls for dosing, monitoring, and automated mixing cycles.

A liquid fertilizer mixer is more than just a tank with blades—it is a complete system that ensures precision, uniformity, and scalability in fertilizer production. By integrating the raw material mixing tank, the mixing tank, and the additive mixing tank, manufacturers can create stable, high-quality liquid fertilizers for a wide range of crops and soils.

With advanced designs, durable materials, and global experience, LANE delivers reliable solutions that help farmers and industries reduce costs, improve productivity, and embrace sustainable agriculture.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments