Liquid Fertilizer from Food Waste: Powering Agriculture with a Circular Economy Mindset

- Efat Elahi

- Aug 11, 2025

- 3 min read

Updated: Aug 11, 2025

Why Liquid Fertilizer from Food Waste Matters

Producing liquid fertilizer from food waste is no longer an experimental idea – it is a proven scalable solution that can simultaneously address two pressing challenges: managing organic waste and providing high-quality nutrients for crops. By converting food residues, leftovers, and expired agricultural products into liquid fertilizer, cities, farms, and agricultural enterprises are transforming once-intractable disposal problems into sources of value.

LANE, with its expertise in waste processing technology and fertilizer production lines, is helping businesses and municipalities close the loop in agriculture, enabling them to produce liquid fertilizer from food waste that meets both environmental and economic goals.

The Agricultural Benefits of Liquid Fertilizer from Food Waste

Liquid fertilizer from food waste isn’t just about waste reduction—it delivers tangible agronomic benefits:

Faster Nutrient Uptake – Liquid formulations are absorbed by plants more quickly than granular fertilizers, supporting rapid growth and healthier yields.

Rich in Organic Matter – Improves soil structure and enhances microbial activity.

Customizable Nutrient Profiles – LANE’s mixing and formulation systems allow precise NPK ratios to match specific crop needs.

Reduced Chemical Dependency – Minimizes reliance on synthetic fertilizers, lowering environmental impact.

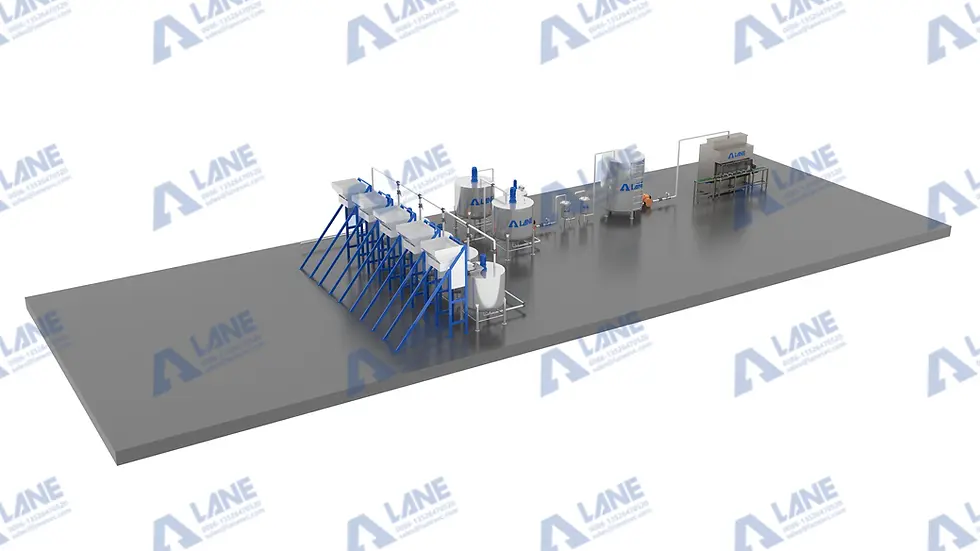

LANE’s Role in Scaling Liquid Fertilizer from Food Waste Production

LANE offers a full-service solution, from equipment supply to process design and after-sales support. Their production lines typically include:

Process Stage | LANE Equipment | Function |

Sorting & Pre-Treatment | Food Waste Sorting Conveyor, Magnetic Separator | Removes contaminants to ensure product purity |

Size Reduction | Breaks down material for efficient fermentation | |

Pathogen Control | Sterilization Tank | Ensures safe, pathogen-free output |

Fermentation | Aerobic or Anaerobic Fermentation Tanks | Converts waste into nutrient-rich liquid |

Filtration | Produces a clean, clog-free final product | |

Formulation & Packaging | Customizes nutrient profile and prepares for distribution |

Case Study: Urban Farm Collaboration

In 2024, an urban agriculture initiative in Singapore partnered with a local waste management company to convert food waste collected from restaurants and supermarkets into high-quality liquid organic fertilizer. The program’s objective was twofold: reduce landfill waste and supply affordable nutrients to the city’s growing number of rooftop farms and community gardens.

The process began at a food waste preprocessing station, where large-capacity industrial food waste shredders reduced waste volume and improved handling. After size reduction, the material was fed into a food waste slurry tank, which homogenized the mixture and prepared it for impurity removal using a rotary drum filter.

The filtered slurry underwent thermal sterilization in a continuous steam sterilizer to eliminate pathogens before entering stainless-steel anaerobic fermentation tanks. Over a period of 15–20 days, microorganisms broke down organic matter, producing nutrient-rich liquid fertilizer while minimizing odor.

The finished fertilizer was transferred to a liquid fertilizer storage tank before being filled into 20L containers using a semi-automatic liquid fertilizer filling machine. These products were then distributed directly to participating rooftop farms, where crops such as leafy greens, herbs, and fruiting vegetables saw measurable improvements in yield and plant health within just one growing season.

This collaboration demonstrated that closed-loop urban food systems can be economically viable while addressing both waste reduction and sustainable agriculture needs. By integrating customized processing equipment with community engagement, the program achieved a 95% diversion rate of food waste from landfills and created a new revenue stream for local farmers.

Sustainability and the Bigger Picture

Using food waste to produce liquid fertilizer directly supports the United Nations' sustainable development goals, such as responsible consumption, climate action, and sustainable agriculture. Moreover, it can also strengthen the local food system by maintaining the recycling of resources.

LANE's approach is not limited to mechanical equipment - they offer on-site training, remote monitoring systems and customized engineering to ensure that each factory operates at its best performance. This means that operators can focus on crops and customers, while LANE is responsible for the technology that achieves this goal.

With landfill disposal costs rising and global agriculture shifting toward eco-friendly practices, liquid fertilizer from food waste offers a unique opportunity to transform a waste stream into a profit stream. LANE’s integrated solutions enable businesses, cooperatives, and municipalities to move quickly from concept to full-scale production.

Whether you are a local government aiming to manage waste sustainably, a farm seeking affordable nutrient sources, or a food processor looking to reduce your environmental footprint, LANE’s liquid fertilizer from food waste production lines provide the speed, efficiency, and reliability needed for long-term success.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments