Large Capacity Organic Fertilizer Plant Design: Building the Future of Sustainable Fertilizer Production

- Efat Elahi

- Jul 23, 2025

- 6 min read

Updated: Aug 1, 2025

The global push for sustainable agriculture has turned organic fertilizers from a niche product into a mainstream necessity. As farms of all sizes seek to reduce chemical use and improve soil health, the demand for organic fertilizers has skyrocketed—and this is where large capacity organic fertilizer plant design comes into play. Unlike small-scale facilities that produce a few tons per day, large capacity plants (capable of 500+ tons daily) are engineered to meet mass demand while maintaining the quality that defines organic products. In this blog, we’ll dive into what makes large capacity organic fertilizer plant design successful, from solving real-world challenges to integrating innovations that keep operations efficient, profitable, and eco-friendly.

Why Large Capacity Organic Fertilizer Plant Design Matters Now

Small organic fertilizer plants have their place, but they can’t keep up with the needs of modern agriculture. A mid-sized farm might use 100 tons of organic fertilizer per season; a large agricultural cooperative could need 10,000 tons or more. This gap is exactly why large capacity organic fertilizer plant design has become a priority.

Consider this: A 1,000-ton-per-day plant can supply enough fertilizer to support 50,000 acres of farmland annually. Without such facilities, farmers would struggle to access consistent, affordable organic options, slowing the shift away from synthetic fertilizers. But building a large capacity plant isn’t just about size—it’s about smart design that handles huge volumes of raw materials (think 1,500 tons of manure and crop waste daily) without sacrificing product quality or environmental standards.

Another key reason is cost efficiency. Large capacity organic fertilizer plant design leverages economies of scale: producing more fertilizer per unit reduces the cost of labor, energy, and raw materials per ton. A small plant might spend 50 to produce a ton of fertilizer; a well-designed large capacity plant can cut that to 30 or less, making organic fertilizers competitive with chemical alternatives.

Core Elements of Effective Large Capacity Organic Fertilizer Plant

Creating a large capacity organic fertilizer plant that works requires focusing on three interconnected elements: flow, flexibility, and durability. These aren’t just buzzwords—they’re the difference between a plant that runs smoothly and one that faces constant bottlenecks.

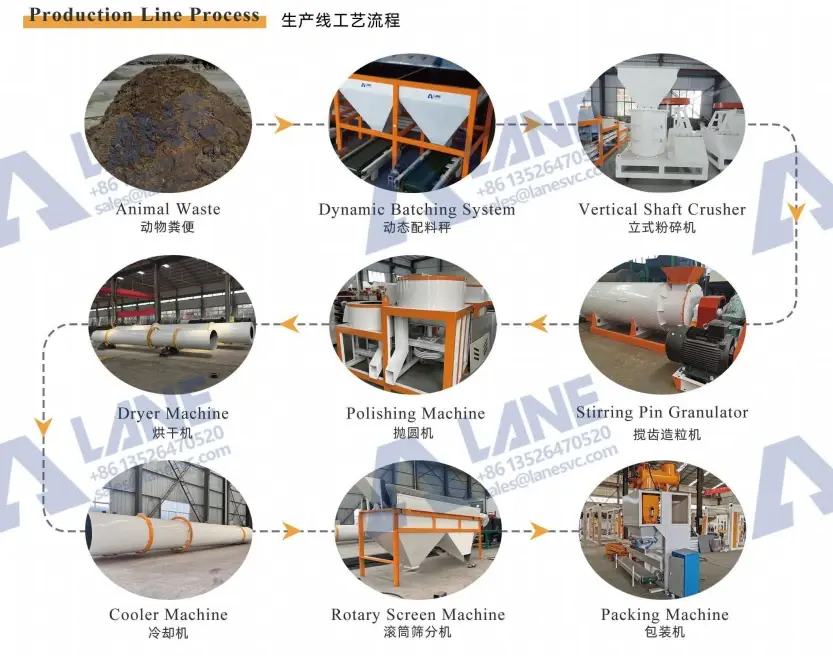

In a large capacity plant, raw materials move from reception to final packaging in a continuous stream. Any blockage can cost thousands of dollars in lost production. Large capacity organic fertilizer plant design addresses this by mapping out a logical flow:Raw materials → Dynamic batching system → Vertical shaft crusher→ Stirring pin granulator → Polishing machine → Dryer and cooler machine → Rotary scree machine → Packaging machine

For example, raw material storage areas are located adjacent to pre-processing equipment to minimize transportation time. Conveyor speeds are adjustable to match the speed of downstream processes—if the fermentation tunnel is processing material faster than expected, the conveyor carrying the material can speed up slightly to keep up. The drying unit is located after the fermentation section, so the hot, moist compost can go directly to the drying stage without accumulating lumps. This carefully designed layout reduces downtime and keeps the entire plant running in sync.

2. Flexibility to Adapt

Organic fertilizer production doesn’t operate in a vacuum. Raw material availability fluctuates—think of a sudden surplus of poultry manure after a local farm expands, or a shortage of crop straw during a dry season. Large capacity organic fertilizer plant design must be flexible enough to handle these changes.

Modular equipment can make a difference. Instead of one large crushers, a plant can use three small, interchangeable crushers. If one requires maintenance, the others can pick up the slack. Similarly, a fermentation system with adjustable channel sizes allows operators to switch between processing a mix that’s higher in manure and one that’s higher in straw without reconfiguring the entire line. This flexibility extends to product type, too: A well-designed plant can switch from producing 4-millimeter pellets for commercial farms to 2-millimeter pellets for home gardeners with just a few adjustments.

3. Durability for the Long Haul

Large plants run around the clock during peak season, putting enormous strain on equipment. A broken part in a granulator or a worn conveyor belt can stop production for hours. That’s why large organic fertilizer plants are designed with durability of every component at the forefront.

Equipment is built with heavy-duty materials: fermentation tunnel walls are made of corrosion-resistant steel to withstand the erosion of acidic compost, and granulator blades are made of hardened alloy to resist wear from abrasive organic materials. Even small details are crucial—conveyor belts are reinforced with steel ropes to withstand heavy loads, and electrical systems are protected by waterproof housings to prevent damage from moisture in the air. Regular maintenance is also built into the design, allowing technicians to easily inspect and repair equipment without shutting down the entire line.

Innovations Shaping Modern Large Capacity Organic Fertilizer Plant Design

Modern large capacity organic fertilizer plant design isn’t about flashy technology for the sake of innovation—it’s about solving real, daily problems that plant operators face. These innovations are tested on the ground, proven to cut costs, reduce headaches, and make operations more reliable. Here are three that are making a tangible difference in working plants today:

1. Automated Granule Size Control for Consistent Output

One of the biggest frustrations in large capacity plants is inconsistent granule size. If 20% of the output is too small (dust-like) and 15% is too large (clumpy), it either gets recycled (wasting time and energy) or sold at a discount. That’s why large capacity organic fertilizer plant design now integrates automated granule size control systems that fix this issue at the source.

Here’s how it works: After granulation, a high-speed camera mounted above the conveyor belt scans every passing granule, measuring size in milliseconds. The data feeds into a computer that adjusts the granulator in real time—if too many small granules appear, it slows the rotation speed; if oversized granules increase, it tweaks the pressure of the binder spray. This system cuts waste by 30% in most plants. Operators no longer have to stop the line to manually adjust settings; the machine self-corrects, keeping production on track.

2. Low-Cost Biogas Systems That Actually Pay Off

Biogas from fermentation isn’t a new idea, but early systems were often too expensive to justify for large plants. Modern large capacity organic fertilizer plant design has fixed this with simplified, scaled-down biogas setups that deliver consistent returns.

A typical setup in a 800-ton/day plant includes a 500-cubic-meter anaerobic digester connected to the fermentation tunnels. It captures methane from decomposing organic matter and feeds it into a small generator (50–100 kW) that powers the plant’s lighting, conveyor belts, and control systems. Excess gas is stored in a 100-cubic-meter tank to keep the generator running during low-production periods (like overnight).

3. Mobile Maintenance Carts for Faster Repairs

Downtime is the enemy of large capacity plants.A broken dryer bearing can cause a four-hour production stoppage if technicians have to search for tools and parts. That’s why today’s high-volume organic fertilizer plant designs include mobile maintenance carts—essentially mobile tool kits tailored to each area of the plant.

Each maintenance cart is equipped with the exact parts and tools needed for its area: the fermentation tunnel maintenance cart comes with replacement gaskets, lubricants, and a set of portable wrenches; the granulator maintenance cart comes with spare blades, adhesive nozzles, and a small drill. Technicians no longer waste time traveling to a central shop—they can simply pick up a maintenance cart and fix the problem on the spot. Plants using these maintenance carts report a 50% reduction in repair time, reducing a four-hour downtime to two hours.

These innovations prove that modern high-volume organic fertilizer plant design is rooted in practicality. They don’t require cutting-edge technology or huge budgets—just focus on solving the day-to-day problems that make or break a plant. By integrating these tools, operators can run more efficiently, reduce costs, and build facilities that thrive in the long term.

LANE: High-quality service and creative experience

With over a decade of dedicated focus on organic fertilizer equipment and system integration, LANE has established itself as a global leader in scalable, efficient, and customized fertilizer plant solutions. From small pilot projects to full-scale industrial operations, LANE brings not just machines—but end-to-end solutions designed to evolve with your business.

What sets LANE apart is its ability to balance engineering precision with biological intelligence. Every piece of equipment, from compost turners to rotary granulators, is designed with both durability and adaptability in mind. The equipment undergoes rigorous quality testing, ensuring continuous performance under demanding 24/7 operations, even in challenging environments with high moisture and acidic inputs.

Rather than offering standalone machines, LANE specializes in turnkey plant design and build services, including:

Site analysis and feasibility studies

Process design and 3D layout modeling

Custom manufacturing of core machinery

Electrical automation and system control integration

Overseas installation and on-site commissioning

Operator training and technical support

Whether a client needs to process 10 tons or 100 tons of organic material per day, LANE’s engineering team develops tailored process flows based on raw material properties, environmental conditions, local regulations, and desired product form (powdered, granulated, bio-enhanced, etc.).

Large capacity organic fertilizer plant design is not just a technical endeavor—it’s a commitment to sustainable agriculture at scale. With careful planning, advanced equipment, and experienced engineering partners like LANE, it’s possible to build facilities that are not only productive but also environmentally responsible and economically viable.

In a world facing both climate stress and food demand, the ability to transform waste into wealth at industrial scale is more important than ever. LANE is proud to be part of that solution—designing systems that feed the future.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments