How to Make Organic Fertilizer: A Complete Guide to Sustainable Farming

- Efat Elahi

- Oct 16, 2025

- 4 min read

With growing awareness of soil health and sustainable agriculture, more farmers and entrepreneurs are looking for ways to reduce chemical dependency and improve soil fertility naturally. One of the most effective methods is learning how to make organic fertilizer — a process that transforms agricultural and livestock waste into nutrient-rich compost or granules that promote healthy crop growth.

Henan LANE Heavy Industry specializes in designing complete organic fertilizer production lines, providing practical and scalable solutions for turning waste into value.

Understanding Organic Fertilizer

Before exploring how to make organic fertilizer, it’s essential to understand what it is. Organic fertilizer is derived from natural sources such as animal manure, crop residues, green waste, or microbial fermentation materials. Unlike chemical fertilizers, which provide synthetic nutrients, organic fertilizers improve soil structure, microbial balance, and long-term fertility.

Typical raw materials include:

Animal manure: chicken manure, cattle dung, pig manure, etc.

Crop residues: straw, rice husk, corn stalks, and sugarcane bagasse.

Industrial organic waste: soybean meal, molasses, coffee grounds, fruit pulp.

Additives: humic acid, amino acid, bone meal, or seaweed extract.

Benefits of Making Organic Fertilizer

Learning how to make organic fertilizer brings multiple advantages:

🌱 Improves soil fertility by enhancing microbial activity and nutrient retention.

💧 Enhances water-holding capacity, reducing drought stress on crops.

🌿 Environmentally friendly, recycling agricultural and livestock waste.

🌾 Boosts crop yields while maintaining soil balance and reducing acidity.

💰 Reduces fertilizer costs and creates business opportunities in green agriculture.

These benefits make organic fertilizer an essential component of sustainable and regenerative farming systems worldwide.

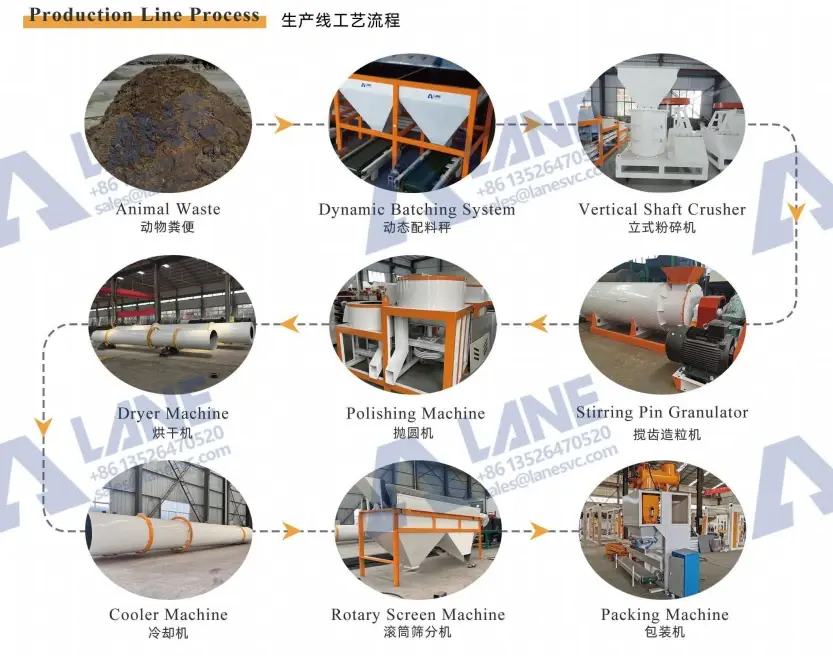

How to Make Organic Fertilizer: Step-by-Step Process

The process of making organic fertilizer can be done manually on a small scale or industrially using a complete organic fertilizer production line. The steps below describe both approaches.

Step 1: Collect and Prepare Raw Materials

Start by collecting organic waste such as manure, plant residues, or food by-products.To achieve efficient composting, maintain a carbon-to-nitrogen ratio (C/N) of around 25–30:1 and a moisture level between 55–60%.

You can adjust these ratios by mixing:

High-nitrogen materials (manure, green leaves)

High-carbon materials (sawdust, straw, or rice husks)

Step 2: Composting and Fermentation

This is the most critical step in how to make organic fertilizer. Composting stabilizes the materials, kills pathogens, and converts waste into a nutrient-rich substrate.

Using a compost turner machine — such as a crawler type compost turner or wheel type compost turner — the pile is turned regularly to supply oxygen and maintain even fermentation.

The compost temperature should reach 55–65°C for at least 10 days to ensure full decomposition.During this time, microorganisms break down organic matter into humus, and the odor gradually disappears.

The fermentation process typically lasts 15–20 days, depending on material type and climate.

Step 3: Crushing and Screening

After fermentation, the composted material may still contain large lumps. Use an organic fertilizer crusher to break down the material into fine particles.Then, use a rotary screening machine to remove impurities and ensure uniform particle size.

Step 4: Mixing and Nutrient Enhancement

To improve nutrient content, mix the composted material with additional ingredients such as humic acid, amino acids, or beneficial microbes. A horizontal mixer or disc mixer ensures thorough blending, preparing the material for granulation or direct packaging.

Step 5: Granulation (Optional)

If you want to produce granular fertilizer, use specialized equipment such as:

Rotary drum granulator

Disc granulator

New type organic fertilizer granulator

Granules are easier to store, transport, and apply in the field. They also dissolve gradually, providing a slow-release nutrient effect for crops.

Step 6: Drying, Cooling, and Packaging

After granulation, the fertilizer must be dried to reduce moisture content to 10–15%.A rotary dryer and cooling machine are used to ensure product stability.

Finally, the finished organic fertilizer is screened once more for uniform size and packed using an automatic packaging machine into 25–50 kg bags or bulk containers.

LANE Heavy Industry provides fully automated systems for how to make organic fertilizer, integrating all these steps into a single, efficient production line.

Equipment Used in Organic Fertilizer Production

A standard organic fertilizer manufacturing line includes:

Compost Turner (Crawler Type / Wheel Type)

Crusher

Mixer

Granulator

Dryer and Cooler

Screening Machine

Automatic Packaging Machine

Belt Conveyor System

LANE Heavy Industry offers complete customization based on capacity, from 1 ton/hour to 20 tons/hour, ensuring efficiency and cost-effectiveness.

How to Make Organic Fertilizer at a Small Scale

If you’re a small farmer or community group, you can still make organic fertilizer without large equipment:

Collect manure and crop residues.

Stack them in a compost pile under a shade or shelter.

Maintain moisture (like a squeezed sponge).

Turn the pile every 5–7 days using a shovel or small compost turner.

After 3–4 weeks, the material becomes dark, crumbly compost ready for use.

This simple method provides an affordable and sustainable fertilizer source for vegetable gardens, orchards, and cash crops.

Industrial Organic Fertilizer Production

For large-scale farming or commercial fertilizer production, an automated organic fertilizer production plant is the best solution.

LANE Heavy Industry designs complete facilities with advanced automation, including temperature monitoring, automatic turning, and intelligent control systems.These plants efficiently handle tons of manure and agricultural waste daily, converting it into high-quality organic fertilizer for domestic and international markets.

Conclusion

Understanding how to make organic fertilizer empowers farmers and entrepreneurs to reduce waste, improve soil health, and build a greener future.By transforming animal manure, crop residues, and organic waste into valuable fertilizer, we close the nutrient loop and promote sustainable agriculture.

With advanced equipment and expert engineering from LANE Heavy Industry, the process of making organic fertilizer becomes efficient, safe, and highly profitable.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments