How to Choose the Right Organic Fertilizer Granulator for Your Farm or Business

- Efat Elahi

- Jan 16

- 4 min read

Table of Contents

Introduction: Why the Right Granulator Matters

Step 1: Analyze Your Raw Material

Step 2: Define Your Production Scale & Goals

Step 3: Understand Granulation Technology Options

Disc Pelletizer (Pan Granulator)

Rotary Drum Granulator

New Type Organic Granulator

Flat Die Pellet Mill

Step 4: Evaluate Machine Quality and Supplier Support

FAQ: Making Your Decision with Confidence

Conclusion: Partner with an Expert

1. Introduction: Why the Right Granulator Matters

Organic fertilizer is the poser face of sustainable agriculture. It not only helps your crop grow it also fixes your soils biological life. The organic fertilizer granulator is the core equipment of any organic fertilizer production line. It directly determining the quality, efficiency, and profitability of your output. However, with various models and technologies available, selecting the wrong organic fertilizer granulator can lead to poor pellet quality, high maintenance costs, and production bottlenecks.

The ideal granulator is not a one-size-fits-all solution. It is the machine perfectly matched to your specific raw materials, output goals, and operational conditions. LANE Heavy Industry offers a range of high-performance organic fertilizer granulators tailored to diverse farming and business needs.

2. Step 1: Analyze Your Raw Material

The characteristics and capacity of your organic fertilizer powder are the main deciding factors while choosing granulator.

Fibrous or Powdery? Materials like manure compost and peat are relatively powdery. Highly fibrous materials (e.g., some crop residues) may require specialized pretreatment or a robust granulator type.

Moisture Content: What is the typical moisture level of your fermented and crushed material? Some granulators require higher moisture (25-40%) as a binding agent, while others can handle lower moisture.

Abrasiveness & Corrosiveness: Materials with high mineral content or certain additives can be abrasive. LANE Heavy Industry builds machines with wear-resistant materials in key areas to handle such challenges.

3. Step 2: Define Your Production Scale & Goals

Your business model dictates the required capacity and automation level.

Small Farm / Homestead: A compact, lower-capacity machine like a Flat Die Pellet Mill may be sufficient for on-farm use.

Mid-Size Organic Fertilizer Business: You’ll need a continuous, automated system like a Disc Pelletizer or Stirring Pin Granulator with consistent hourly output (e.g., 1-5 tons for disk, 1-10 tons for stirring pin).

Large-Scale Commercial Plant: High-tonnage production requires heavy-duty equipment like a Rotary Drum Granulator, integrated into a fully automatic production line with drying, cooling, and packaging.

4. Step 3: Understand Granulation Technology Options

LANE Heavy Industry offers several core technologies, each with strengths:

Disc Pelletizer (Pan Granulator):

Best For: Producing uniform, spherical pellets with excellent size control.

Process: Material is fed onto a rotating, inclined disc. A fine mist of liquid binder is sprayed, causing particles to coalesce into balls through a rolling motion. The pellet size is easily adjusted by changing the disc angle and rotation speed.

Rotary Drum Granulator:

Best For: Large-scale, continuous production of rounded granules.

Process: Material is tumbled in a long, rotating drum. Liquid binder is sprayed inside. The tumbling action creates a layering effect, forming dense, polished granules. It’s known for high capacity and durability.

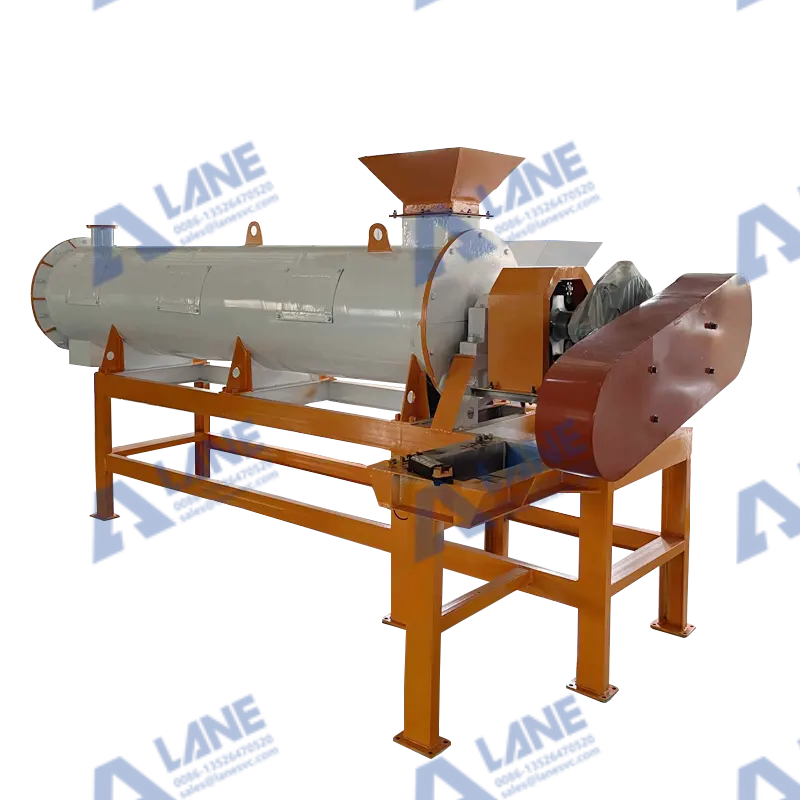

Stirring Pin Granulator:

Best For: A wide range of organic materials, especially those where controlling moisture is beneficial.

Process: Uses high-speed mechanical stirring and centrifugal force to agitate and tumbling to make compost into granules. It often requires less additional moisture and is versatile for various formulations.

Flat Die Pellet Mill:

Best For: Small to medium-scale operations, or for producing cylindrical, high-density pellets from tougher, fibrous materials.

Process: Powder is pressed through holes in a flat die by rollers, creating compact extruded pellets cut to length. It creates a different pellet shape but is highly effective.

5. Step 4: Evaluate Machine Quality and Supplier Support

The machine’s construction and the supplier’s service are as important as the technology.

Build Quality: Look for heavy-duty frames, robust gearboxes, and wear plates in high-abrasion areas. LANE machines are built for 24/7 industrial use.

After-Sales Service: Ensure the supplier offers installation guidance, operational training, and ready access to spare parts. A reliable partner like LANE Heavy Industry minimizes your downtime risk.

Integrated Line Design: Consider if you need just the organic fertilizer granulator or a complete line (crusher, mixer, dryer, cooler). A supplier who can engineer the entire system ensures compatibility and optimal performance.

6. FAQ: Making Your Decision with Confidence

Q1: What’s the most cost-effective granulator type for a startup?

A: For a new business with standard organic compost powder, a Disc Pelletizer often offers an excellent balance of reasonable investment, good pellet quality, and manageable operational complexity. LANE can provide models scaled to your initial budget and capacity.

Q2: Can one granulator handle all different types of materials?

A: While some machines like the New Type Organic Granulator are highly versatile, extreme changes in material (e.g., from fine peat to very fibrous mushroom substrate) may require process adjustments or different die/liner configurations. Discuss your full range of planned feedstocks with your LANE engineer.

Q3: How much space do I need for a granulation system?

A: Space varies widely. A simple granulator with a mixer might fit in a small workshop. A full production line with fermentation, drying, cooling, and screening can require a significant industrial shed. Share your available space during consultation.

Q4: What are the ongoing maintenance requirements?

A: Regular lubrication, inspection of wear parts (like disc liners or die rings), and cleaning are essential. LANE provides clear maintenance manuals and identifies high-wear parts for easy monitoring and replacement.

Q5: Does LANE Heavy Industry offer customized solutions?

A: Absolutely. While we have standard models, we frequently customize granulators based on specific client requirements for capacity, material traits, and integration with existing equipment.

7. Conclusion: Partner with an Expert

Choosing the right organic fertilizer granulator from LANE Heavy Industry hinges on matching raw materials, production scale, and product goals. It impacts on your long term productivity and product quality. By systematically analyzing your materials, scale, and goals, you can narrow your options effectively. LANE’s equipment ensures your production line runs efficiently, turning organic waste into sustainable profits.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments