How Does a Food Waste to Organic Fertilizer Processing Line Transform Waste into Agricultural Gold?

- Efat Elahi

- Jul 24, 2025

- 4 min read

Updated: Aug 1, 2025

Food waste is a global crisis, with more than 1.3 billion tons of food thrown away each year, enough to feed nearly 3 billion people. Instead of ending up in landfills and emitting harmful methane, food waste can be converted into high-quality organic fertilizer through advanced food waste organic fertilizer processing line.

This sustainable approach not only reduces environmental pollution, but also produces nutrient-rich fertilizer that improves soil health and increases crop yields. This article will explore how modern processing technologies can effectively transform food scraps into valuable organic fertilizer to complement existing waste management solutions.

Why Food Waste Needs Urgent Solutions

Food waste is not just a moral or economic issue, it’s an environmental one. When food waste decomposes in landfills, it releases methane, a greenhouse gas far more harmful than carbon dioxide. In addition, when food is thrown away, the energy, water, and labor required to produce it are wasted. Tackling this crisis requires a strong, decentralized solution, which is exactly what modern food waste fertilizer systems aim to achieve.

What Is a Food Waste to Organic Fertilizer Processing Line?

The integrated system transforms food waste, from household leftovers to large-scale industrial food waste, into nutrient-rich organic fertilizer. Through a series of biological and mechanical processes, the system converts waste into sustainable agricultural input.

Unlike traditional composting, which is often time-consuming and labor-intensive, the food waste to organic fertilizer production line focuses on efficiency, hygiene, and scalability. It includes modules for sorting, shredding, dehydration, fermentation, and granulation or liquid conversion, depending on the desired end product.

How Does a Food Waste to Organic Fertilizer Processing Line Work?

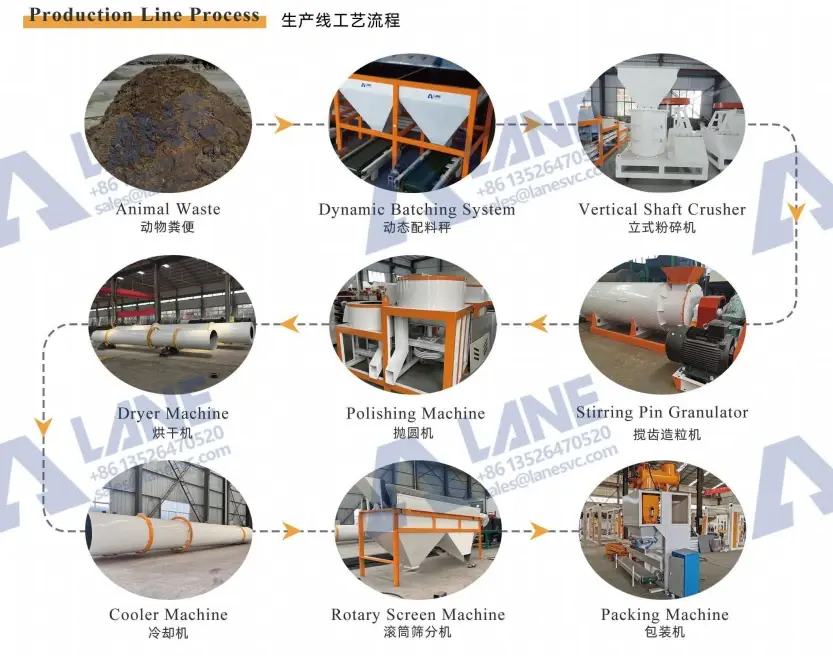

A fully integrated food waste to organic fertilizer processing line follows a systematic approach to ensure efficient decomposition, sterilization, and nutrient recovery. The key stages include:

1. Pre-Treatment: Sorting and Crushing

Automatic sorting systems remove non-organic contaminants (plastics, metals, glass).

Crushers and shredders break down food waste into smaller particles for faster decomposition.

2. Fermentation & Composting

Closed aerobic fermentation tanks accelerate breakdown using microbial activity.

Temperature & moisture control ensures optimal conditions for decomposition (typically 55–70°C to kill pathogens).

Compost turners or agitators promote oxygen flow, preventing foul odors.

3. Granulation & Blending

Granulators shape the compost into uniform pellets for easier application.

Nutrient enrichment (optional) adds beneficial microbes, NPK, or trace minerals.

4. Drying & Sterilization

Rotary drum dryers reduce moisture content to below 30%, making the material easier to process.

High-temperature sterilization eliminates harmful bacteria and weed seeds.

Vibrating screens separate fine fertilizer from coarse residues (which can be re-processed).

Automatic bagging machines pack the final product for distribution.

Beyond Sustainability: Agricultural and Economic Impact

Organic fertilizer produced from food waste is rich in nutrients and beneficial microorganisms, ideal for improving soil health, increasing crop yields and reducing reliance on chemical fertilizers. In addition, communities and local governments can use these systems as part of green jobs projects to enhance economic resilience.

Farms can directly recycle food waste into usable fertilizer using facilities on-site or nearby, effectively closing the loop between consumption and production. This will promote a self-sustaining ecosystem that fits perfectly with the principles of regenerative agriculture.

Case Studies: Successful Implementations of Food Waste to Fertilizer Systems

1. The Copenhagen Solution - Turning City Waste into Farm Gold

Denmark's capital, Copenhagen, has pioneered an integrated approach that combines urban food waste with rural agricultural needs. Their state-of-the-art processing facility on the island of Amager receives food waste from thousands of households and businesses through a dedicated collection system. What's special about this project is their collaboration with local farmers. Jens Petersen, a potato farmer I interviewed, shared how using Copenhagen's compost increased production by nearly 15% while reducing the need for chemical fertilizers. The facility processes about 70,000 tons of food waste each year, turning Copenhagen's food waste into high-quality organic fertilizer, which is in high demand among organic farmers in Denmark.

2. Bali's Zero Waste Revolution

In Ubud, Bali, a community-led project called "maggot farming" is gaining ground in surprising ways. Small eateries (local restaurants) and hotels sort their food waste and send it to community processing centers. There, black soldier fly larvae break down the waste at an astonishing rate. Pak Wayan, who runs one such processing center, showed me how they harvest the protein-rich larvae (to be sold as chicken feed) and the remaining compost. What started as a pilot project now involves more than 200 businesses, producing enough organic fertilizer to supply dozens of local vegetable farms and Bali's famous rice terraces.

3. Toronto's High-Tech Composting Success

Canada’s largest city, Toronto, has developed one of the most advanced organic waste treatment systems in North America. Its Dufferin Organics Facility uses automated sorting technology to process a wide range of food waste from Toronto’s multicultural population. Facility Manager Sarah Chen explains how they’ve refined their process to handle everything from Caribbean food waste to East Asian ingredients. The resulting compost is so nutritious that it’s been certified organic and even used in the city’s urban agriculture program. Last year, they processed more than 50,000 tons of food waste, helping Toronto reach its 70% waste diversion rate goal.

These examples show that successful food waste to organic fertilizer processing lines are not just about technology, but about building meaningful connections between food waste producers and agricultural users. Whether it is a high-tech urban facility or a community-led insect farm, each solution is tailored to the local context. What they have in common is that food waste is not garbage, but a valuable resource that can nourish new growth.

From Waste to Worth

A food waste to organic fertilizer processing line offers more than just a waste solution, it represents a paradigm shift towards sustainable agriculture, environmental stewardship and economic empowerment. By turning food waste into a resource, we not only reduce our ecological footprint, but also enrich our soils and communities.

For businesses, municipalities or agricultural cooperatives looking to improve their environmental performance and resource efficiency, investing in an integrated processing line is a step towards a greener, more circular future.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments