How a Rice Straw Compost Fertilizer Line Supports Eco-Friendly Agriculture

- Efat Elahi

- Sep 12, 2025

- 4 min read

Rice is one of the most widely cultivated crops in the world, and every harvest leaves behind a massive amount of straw. Traditionally, farmers often dispose of straw through open-field burning, which causes air pollution, carbon emissions, and health problems in rural communities. In contrast, modern technology offers a sustainable alternative: the rice straw compost fertilizer line.

By using a rice straw compost fertilizer line, farmers and agribusinesses can transform what was once considered waste into a valuable organic fertilizer. This not only improves soil fertility and crop yields but also helps reduce environmental pollution and supports circular agriculture.

Why Rice Straw Composting Matters

Environmental Protection

Burning rice straw releases large amounts of carbon dioxide, particulate matter, and toxic gases. Composting prevents this, improving air quality.

Soil Health Improvement

Compost produced from rice straw enriches organic matter, enhances microbial diversity, and improves water retention in soils.

Nutrient Recycling

Rice straw contains nitrogen, potassium, phosphorus, and silica, which can be recycled back into the soil when properly composted.

Compliance with Regulations

Many countries are now restricting or banning straw burning. Composting is a legal and sustainable solution.

Economic Opportunities

The rice straw compost fertilizer line allows farmers to produce fertilizer for personal use or commercial sale, generating new income streams.

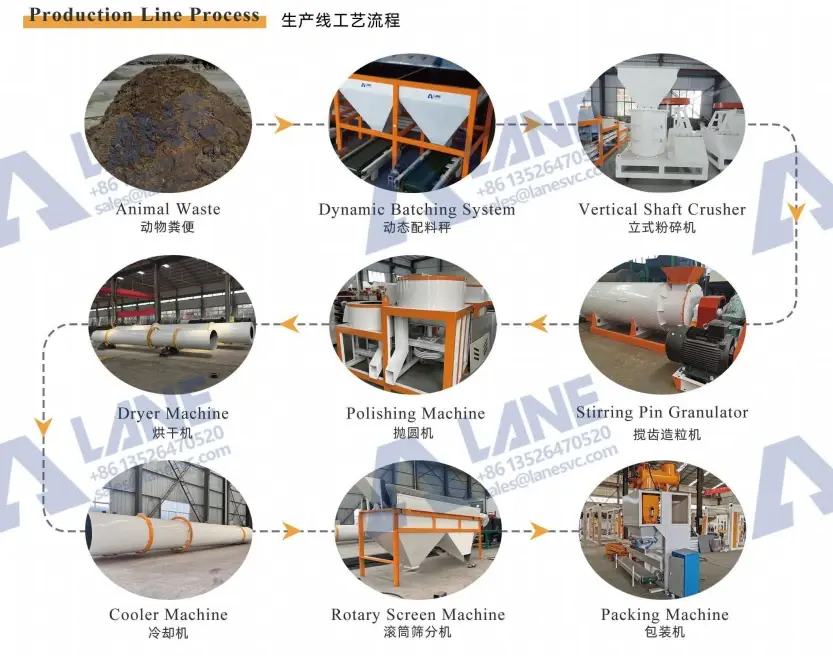

Workflow of a Rice Straw Compost Fertilizer Line

A modern rice straw compost fertilizer line consists of several well-coordinated steps supported by specialized equipment:

1. Straw Collection and Shredding

Rice straw is collected after harvest and fed into a shredding machine, cutting it into smaller pieces (around 3–5 cm). This increases aeration and accelerates decomposition.

2. Composting and Fermentation

The shredded straw is mixed with nitrogen-rich materials such as livestock manure to balance the carbon-to-nitrogen ratio. It is then piled into windrows or fermentation pits. A crawler type compost turner or wheel type compost turner is used to aerate the piles, regulate temperature, and maintain optimal moisture.

3. Crushing and Mixing

After fermentation, the semi-finished compost is processed through a crusher to break down lumps. The crushed material is then blended in a horizontal mixer with additives such as beneficial microbes or mineral nutrients to enhance fertilizer quality.

4. Granulation

The mixed material is granulated using machines such as a disc granulator, rotary drum granulator, or stirring pin granulator. Granules make fertilizers easier to transport, apply, and store.

5. Drying and Cooling

Freshly formed granules contain moisture that must be reduced. A rotary drum dryer lowers the moisture content, followed by a rotary drum cooler that stabilizes granules and prevents clumping.

6. Screening and Polishing

The dried fertilizer passes through a rotary screener to separate qualified products from oversized or undersized granules. A polishing machine can further improve granule appearance and consistency.

7. Packaging and Storage

The finished product is packaged using an automatic packaging system into bags or bulk containers, ready for use or sale.

Advantages of a Rice Straw Compost Fertilizer Line

Eco-Friendly Solution: Reduces pollution from straw burning and cuts greenhouse gas emissions.

Improved Soil Fertility: Enhances organic matter content and boosts crop yields.

Efficient Resource Recycling: Converts agricultural waste into valuable fertilizer.

Market Value: Granulated compost has high commercial demand in domestic and international markets.

Customizable Systems: A rice straw compost fertilizer line can be scaled for smallholder farms or large industrial plants.

Integration with Other Wastes: Straw can be composted with manure, food residues, or bio-waste for improved nutrient balance.

Case Example: Thailand’s Rice Farming Cooperative

In Thailand, rice farmers often faced strict regulations against burning straw but lacked alternatives. A cooperative introduced a rice straw compost fertilizer line with shredders, compost turners, and a rotary drum granulator. Within two years, they converted thousands of tons of straw into organic fertilizer, reducing air pollution and generating new revenue by selling compost to neighboring farms.

Case Example: India’s Large-Scale Composting Facility

In Punjab, India—where straw burning causes severe air pollution each winter—a large agribusiness established an industrial rice straw compost fertilizer line. Processing over 80,000 tons of straw annually, the facility combined rice straw with dairy manure to produce organic fertilizer. Equipped with dryers, coolers, and packaging systems, the plant created high-quality fertilizers for both local markets and exports. Farmers reported reduced chemical input costs and better soil fertility after adopting the product.

Integration with Circular Agriculture

The rice straw compost fertilizer line represents more than just waste treatment; it supports a circular agricultural model. Instead of being discarded, straw becomes a nutrient source that returns to the soil, closing the loop in the farming system. When combined with other wastes such as livestock manure, this technology simultaneously solves multiple waste challenges while creating eco-friendly fertilizers.

Future Outlook

As governments continue to impose restrictions on open burning and consumers demand eco-friendly farming practices, the adoption of rice straw compost fertilizer lines will increase. Future systems are expected to integrate smart technologies such as IoT-based monitoring for temperature and moisture, automated compost turning, and energy-efficient drying. These upgrades will make the process faster, more precise, and more sustainable.

International demand for organic and bio-based fertilizers is also projected to rise sharply, offering new business opportunities for farms and cooperatives investing in rice straw compost fertilizer lines today.

The rice straw organic fertilizer production line is a powerful solution to one of agriculture’s most pressing challenges: straw waste management. By converting residues into high-quality organic fertilizer, it reduces pollution, enhances soil fertility, and provides farmers with new income opportunities.

From small cooperatives in Thailand to large industrial facilities in India, real-world examples show how this technology creates value while protecting the environment. Looking ahead, the rice straw compost fertilizer line will continue to play a vital role in sustainable agriculture, helping farmers turn waste into opportunity and building a cleaner, greener future for global farming communities.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments