High Yield Organic Fertilizer Production Technology: Driving Sustainable Agriculture

- Efat Elahi

- Sep 16, 2025

- 4 min read

As the demand for food grows worldwide, agriculture faces the dual challenge of increasing crop productivity while maintaining soil health. Traditional chemical fertilizers, though effective in boosting short-term yields, have long-term drawbacks such as soil degradation, water contamination, and reduced biodiversity. To address these challenges, high yield organic fertilizer production technology has emerged as a sustainable and efficient solution.

This technology allows farmers to process agricultural waste, livestock manure, and other organic resources into nutrient-rich fertilizers that not only sustain crop growth but also improve soil fertility over time. By combining advanced composting techniques with modern equipment, the system enables large-scale production of high-quality organic fertilizers tailored for different crops and regions.

What is High Yield Organic Fertilizer Production Technology?

High yield organic fertilizer production technology refers to the methods and equipment used to maximize both the output and efficiency of organic fertilizer production. Unlike small-scale composting, this approach focuses on industrial-level setups that can process hundreds or thousands of tons of raw material annually.

The core idea is to accelerate microbial activity, ensure nutrient stability, and maintain product quality, all while handling large volumes of organic waste. With optimized aeration, controlled temperature, and automated equipment, producers can achieve consistent high yields of organic fertilizer suitable for commercial farming and export markets.

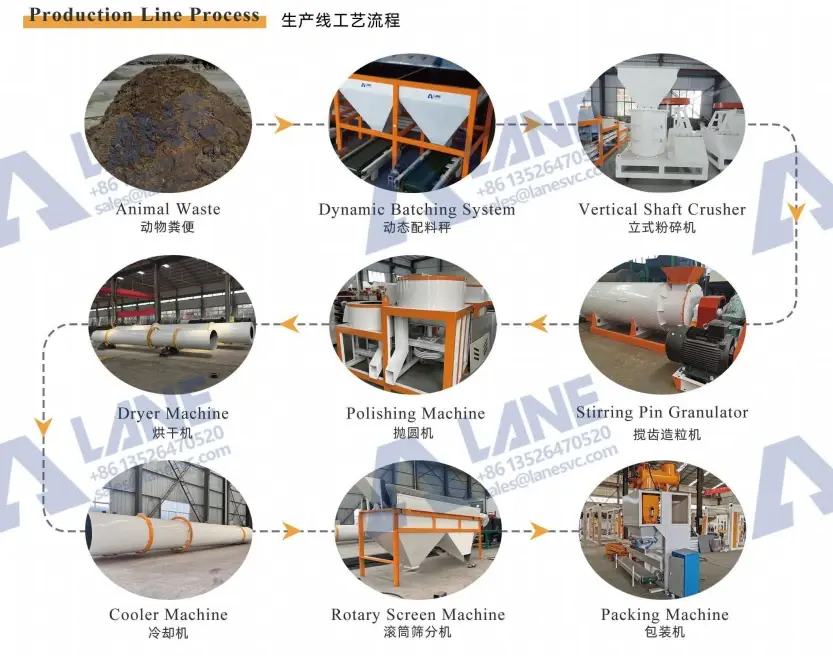

Detailed Workflow of High Yield Organic Fertilizer Production Technology

The workflow combines biological fermentation with mechanical processing to achieve efficient production.

Step 1: Raw Material Collection and Pre-treatment

Common raw materials include livestock manure (chicken, cow, pig), crop residues (straw, husks), food waste, and agricultural by-products. Materials are first balanced for carbon-to-nitrogen (C/N ratio around 25–30) and adjusted for moisture (ideal range 55–65%). Excess water is removed using an inclined dewatering machine.

Step 2: Composting and Fermentation

Raw materials are piled in windrows or placed inside fermentation grooves. A crawler type compost turner maintains proper aeration. During fermentation, heat from microbial activity raises temperatures above 55°C, killing pathogens and weed seeds. Fermentation generally takes 15–25 days, depending on conditions. Adding microbial inoculants further shortens the cycle and improves nutrient balance.

Step 3: Crushing and Screening

The fermented material is processed in a semi-wet material crusher or vertical shaft crusher to break down clumps. A rotary screener then separates qualified compost from oversized particles, ensuring uniform texture.

Step 4: Mixing with Additives

For tailored formulations, compost is combined with mineral nutrients or beneficial microbes in a horizontal mixer. This step allows producers to customize fertilizers for specific soil types and crop requirements.

Step 5: Granulation for High Yield Fertilizer

To improve handling and marketability, many facilities convert compost into granules. An efficient organic fertilizer granulator for high output, such as a stirring pin granulator, disc granulator, or rotary drum granulator, is used. These machines ensure uniform granules with strong hardness and ideal nutrient release properties.

Step 6: Drying and Cooling

Granules are dried in a rotary drum dryer to reduce moisture to below 10%, preventing clumping during storage. A rotary cooler lowers the temperature, stabilizing the product.

Step 7: Screening and Polishing

Another round of rotary screening ensures uniform granule size. A polishing machine improves granule appearance, increasing product competitiveness in the market.

Step 8: Packaging and Storage

Finished fertilizers are measured and sealed using an automatic packaging machine. Moisture-proof bags keep the product stable during transport and storage.

Advantages of High Yield Organic Fertilizer Production Technology

Large-Scale Efficiency

Capable of processing hundreds of tons of organic material daily, meeting the demands of commercial agriculture.

Nutrient-Rich Products

Retains organic matter and beneficial microbes, improving soil fertility and long-term crop productivity.

Environmental Sustainability

Reduces waste, prevents pollution, and promotes circular agriculture by recycling organic materials.

Economic Benefits

Lowers dependency on costly chemical fertilizers, while creating new income streams from fertilizer sales.

Market Competitiveness

Granular products are easy to transport, apply, and store, giving them higher market value.

Case Example 1: Large-Scale Facility in India

An agricultural cooperative in India installed a high yield organic fertilizer production technology system to manage cow manure and crop residues. The line included fermentation tanks, granulators, and dryers, producing over 50,000 tons of organic fertilizer annually.

Farmers in the region reported significant yield improvements in rice and sugarcane fields, while the cooperative generated additional revenue from fertilizer sales. This project not only solved a waste disposal issue but also strengthened food security.

Case Example 2: Sustainable Farming Initiative in Kenya

In Kenya, a public-private partnership introduced a high yield organic fertilizer production technology plant to process urban organic waste and livestock manure. The facility produced high-quality granules, distributed to smallholder farmers at affordable prices.

The initiative reduced reliance on imported fertilizers, cut waste disposal costs, and improved soil fertility across the region. For many farmers, access to affordable organic fertilizers meant higher yields and increased household income.

Challenges and Solutions

Moisture Management

Excess water in raw materials slows fermentation. Using an inclined dewatering machine and balancing inputs with dry crop residues solves this issue.

Odor Control

Improper aeration during composting creates unpleasant smells. Regular turning, microbial inoculants, and covered fermentation systems significantly reduce odors.

High Initial Investment

Production lines require substantial upfront costs. Solutions include phased investment, government subsidies, or cooperative ownership models.

Market Competition

Chemical fertilizers often dominate due to low prices. Organic fertilizers can compete by emphasizing long-term soil benefits and positioning products in premium organic markets.

Innovation and Future Trends

The next generation of high yield organic fertilizer production technology will focus on automation and smart farming integration. IoT-based monitoring systems will track temperature, pH, and nutrient levels in real time. AI algorithms will optimize fermentation cycles, reduce labor costs, and improve product consistency.

Renewable energy applications, such as solar-powered compost turners and biogas recovery, will reduce carbon emissions. Moreover, microbial biotechnology will introduce specialized inoculants that speed up composting and enhance fertilizer effectiveness. These innovations will make organic fertilizer production not only more efficient but also more environmentally friendly.

The high yield organic fertilizer production technology represents a powerful tool for modern agriculture. By transforming organic waste into nutrient-rich fertilizers, it simultaneously addresses environmental challenges, improves crop yields, and creates new economic opportunities.

From India’s large-scale cooperatives to Kenya’s sustainable farming initiatives, real-world cases show the transformative power of this technology. With continued innovation, automation, and global adoption, high yield organic fertilizer production technology will remain central to achieving food security and sustainable farming in the years ahead.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments