High-Efficiency Organic Fertilizer Granulation Plant: Smart Solutions for Sustainable Agriculture

- Efat Elahi

- Sep 30, 2025

- 3 min read

A high-efficiency organic fertilizer granulation plant is the backbone of modern sustainable farming. With growing global awareness of soil health and eco-friendly agriculture, demand for efficient, scalable, and reliable fertilizer production systems is higher than ever. Farmers, agribusinesses, and cooperatives need advanced facilities that can process raw organic materials into nutrient-rich fertilizers quickly and cost-effectively.

At LANE Heavy Industry, we provide turnkey solutions for organic fertilizer plants. From composting and crushing to granulation, drying, and packaging, our equipment is engineered to maximize efficiency, reduce costs, and deliver consistent high-quality granules.

Why Choose a High-Efficiency Organic Fertilizer Granulation Plant?

Efficiency is the key factor that distinguishes a basic plant from a high-efficiency organic fertilizer granulation plant. The benefits include:

Faster Processing: Reduce production cycle time by up to 40%.

Higher Granule Quality: Uniform particle size, strong hardness, long shelf life.

Energy Savings: Optimized drying and cooling systems cut energy costs.

Scalable Production: Suitable for both small-scale farmers and large industrial operators.

Eco-Friendly: Reduces waste, emissions, and chemical fertilizer dependency.

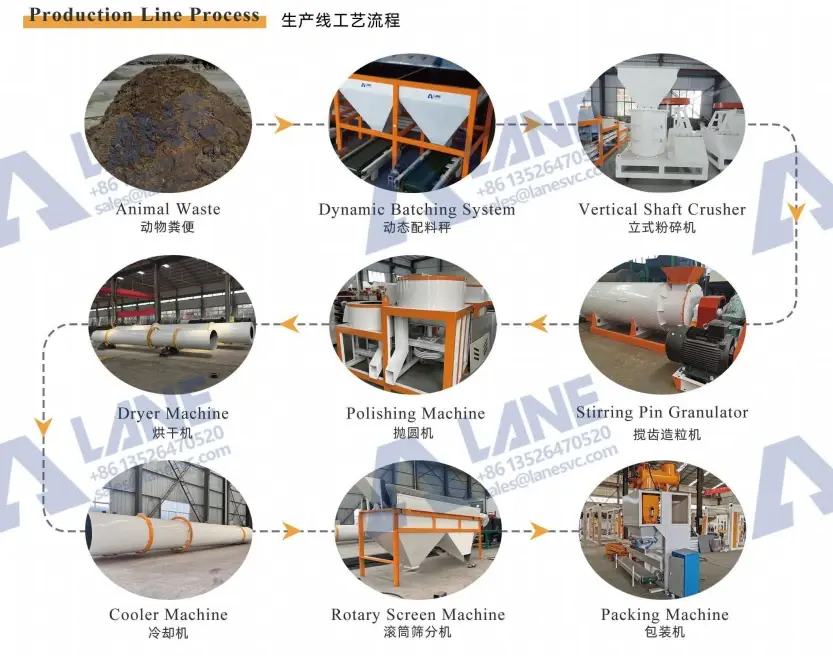

Key Components of a High-Efficiency Organic Fertilizer Granulation Plant

A high-efficiency organic fertilizer granulation plant is not just a collection of machines—it is a fully integrated production line where each stage is designed to maximize efficiency, ensure product quality, and reduce operational costs. With LANE’s advanced engineering and years of experience, every component works seamlessly together to create a smooth and reliable process.

The production starts with fermentation, where raw materials like animal manure, crop residues, or food waste are processed using LANE’s crawler or groove compost turners. These machines accelerate aerobic fermentation, eliminate harmful pathogens, and stabilize organic matter, ensuring a clean and nutrient-rich base material. Our turners are designed for low energy consumption and high turning capacity, which helps farmers achieve faster composting cycles.

Once the compost matures, it is directed to the crushing stage. LANE’s vertical shaft crusher crushers ensure that clumps are broken down into uniform fine particles. This step is critical for smooth granulation and prevents blockages further along the line. The material then flows into the mixing unit, where disc or horizontal mixers blend nutrients evenly. Our mixers are engineered to deliver consistent formulas, which ensures every bag of fertilizer meets strict quality standards.

The heart of the process is granulation. LANE offers a choice of disc granulators, rotary drum granulators, and stirring pin granulators, each tailored to different material types and production capacities. These machines form durable and uniform granules that farmers prefer for application in the field. After granulation, the product passes through drying and cooling systems, which are optimized to save energy while reducing moisture and enhancing granule strength.

Next comes screening, where our precision rotary screeners separate qualified granules from oversized or undersized particles, recycling them back to the process for zero waste. The final touches are completed in the coating machine, which adds a protective layer to prevent caking and improve storage performance. Finally, automatic packing scales ensure fast, accurate, and dust-free packaging, ready for sale and distribution.

What makes this flow truly high-efficiency is the synergy between every unit. LANE provides not only robust and reliable machinery but also complete production line design, installation support, operator training, and long-term maintenance services. By choosing LANE, clients are not just investing in machines—they are securing a sustainable, profitable, and future-proof fertilizer business.

Case Study : Large-Scale Poultry Farm in Vietnam

A large poultry farm in southern Vietnam, raising over 500,000 chickens, was struggling with the daily challenge of manure management. Open-air composting caused odor issues and created risks under stricter local environmental regulations.

To solve this, the farm worked with LANE to build a high-efficiency organic fertilizer granulation plant. Using crawler-type compost turners, the raw manure was converted into stable compost in just 15–20 days, much faster than traditional methods. The material then went through LANE’s crusher and mixer before being processed in a rotary drum granulator, producing strong, uniform fertilizer granules.

Within months, the farm reduced waste-handling costs, eliminated odor complaints, and created a new revenue stream by selling its branded organic fertilizer to nearby rice and coffee growers. Thanks to LANE’s reliable equipment and technical support, the farm successfully turned a waste problem into a profitable, sustainable solution.

A high-efficiency organic fertilizer production line is the ideal solution for farmers and agribusinesses aiming to reduce waste, improve soil fertility, and maximize profits. By investing in a modern plant, you not only enhance production efficiency but also contribute to sustainable agriculture.

With LANE Heavy Industry’s expertise, you gain a trusted partner offering durable equipment, global service, and innovative technology. Whether you run a small farm or manage a large enterprise, our solutions ensure that your fertilizer production is efficient, profitable, and eco-friendly.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments