Granular Organic Fertilizer Production Line – Boosting Sustainable Agriculture with Precision Technology

- Efat Elahi

- Jul 31, 2025

- 4 min read

Updated: Aug 1, 2025

Ever wondered why so many farms and agri-businesses are moving toward a granular organic fertilizer production line?It’s not just a trend. Granular organic fertilizers are easier to apply, last longer in the soil, and give crops a steady nutrient supply without the big spikes and drops that come with quick-release fertilizers.

At LANE, we help farmers and producers set up granular organic fertilizer production lines that match their materials, their goals, and their budgets. From handling raw manure to packaging clean, uniform granules, our systems are designed to keep things running smoothly day after day.

Why Granular Organic Fertilizer Is in Demand

Granular organic fertilizer solves problems that powder fertilizer can’t.For one, the granules don’t blow away or create dust clouds when applied in the field. They also break down more slowly, feeding plants for weeks rather than days. This means healthier crops and less fertilizer loss.

And here’s another plus: many farmers say that once they switched to granular organic fertilizer production lines, they started selling more of their own fertilizer locally, creating a new income stream. That’s the kind of win–win modern agriculture needs.

LANE’s Granular Organic Fertilizer Production Line

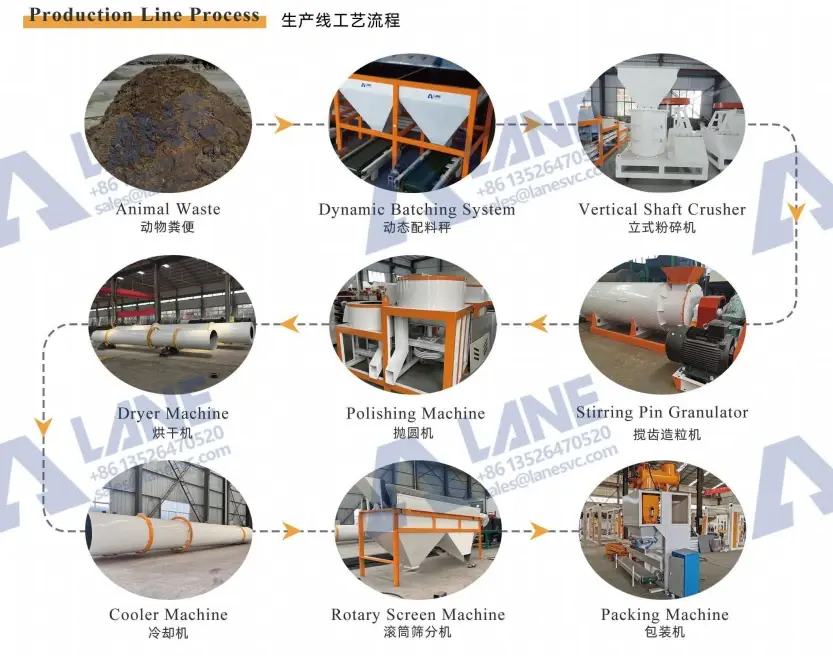

Every production line has its own flow, but a typical LANE setup includes:

Raw Material Crusher – For breaking down poultry manure, crop waste, or compost into fine powder.

Mixing Unit – Where different nutrients are blended for a balanced formula.

Granulator – The machine that shapes the powder into durable granules.

Dryer & Cooler – To remove excess moisture and keep granules in perfect condition.

Screening Machine – Ensures only uniform granules move forward; rejects are recycled.

Coating Machine – Adds a protective layer so granules don’t clump in storage.

Packaging System – Fast, precise bagging for shipping or farm use.

The equipment is tough, low-maintenance, and made to run in continuous production environments without constant repairs.

How the Process Works – Step-by-Step

Operating a granular organic fertilizer production line involves a series of carefully coordinated steps, each supported by specialized equipment to ensure consistent quality and high efficiency. A modern plant operates as follows:

1. Raw Material Preparation

The process begins by collecting organic raw materials such as poultry manure, livestock manure, crop residues, composted plants, or other biodegradable waste. These raw materials are fed into a horizontal semi-wet material crusher or a vertical shaft crusher, which pulverizes them into fine, uniform particles. This stage is crucial for removing clumps and ensuring that each particle in the final product has a consistent nutrient profile.

2. Uniform Mixing and Nutrient Formulation

The crushed materials are transferred to a horizontal mixer or double shaft mixer, where they are blended with other essential additives—such as humic acid, biochar, amino acids, or trace mineral powders—to create a balanced fertilizer formulation. This mixing process ensures that every portion of the material contains the correct nutrient ratio for crops.

3. Granulation – The Heart of the Process

Once mixed, the material enters the double roller granulator or stirring pin granulator, where powder particles are compacted and shaped into round, dense granules. This step transforms loose powder into stable, easy-to-handle fertilizer granules, improving storage life and field application efficiency.

4. Drying and Cooling

Freshly formed granules contain excess moisture and need to be stabilized. They pass through the rotary drum dryer, which uses hot air circulation to reduce moisture to safe storage levels. Immediately after drying, the granules move to the Rotary Drum Cooler to bring them to ambient temperature, preventing caking during packaging and storage.

5. Screening for Quality Control

Granules then pass through the rotary screener, which separates qualified products from oversized and undersized particles. Oversized granules are sent back to the crusher for re-processing, while undersized powders are returned to the granulator for a second chance at forming perfect granules.

6. Surface Coating

To prevent moisture absorption and improve shelf life, granules are fed into the fertilizer coating machine. A thin layer of protective coating—often mineral oil or an anti-caking agent—is applied, ensuring smooth flow during spreading and extended storage stability.

7. Packaging and Storage

Finally, the finished granules are weighed and bagged using an automatic Fertilizer Packing Scale or fully automatic packaging machine. Bags are sealed, labeled, and stored in a dry warehouse, ready for shipment to farms, distributors, or retail stores.

One poultry farm in Southeast Asia installed a granular organic fertilizer production line from LANE with a capacity of 10 tons per hour. Before that, manure disposal was costly and often a headache. After the upgrade, they turned waste into market-ready fertilizer, saved on external purchases, and even started selling branded bags to nearby farms.

They told us the biggest surprise was how little downtime they had. “We used to stop every other week for repairs,” the manager said. “Now we run for months without a major interruption.”

A granular organic fertilizer production line is more than just a piece of equipment; it transforms waste into profit, strengthens farm independence, and supports a greener future.LANE can help you design and install a production line that operates reliably, produces high-quality fertilizer, and stays within your budget. Whether you're upgrading an old plant or building a new one, we can ensure your system's long-term success.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments