Environmentally Friendly Organic Fertilizer Granulation Plant: Turning Waste into Healthy Soil

- Efat Elahi

- Sep 18, 2025

- 4 min read

Environmentally friendly organic fertilizer granulation plant — this phrase describes more than a factory: it describes a practical pathway for cities, farms, and food companies to close nutrient loops, reduce pollution, and supply farmers with stable, easy-to-apply organic fertilizers. An environmentally friendly organic fertilizer granulation plant converts heterogeneous organic wastes (manure, crop residues, municipal sludge, food processing by-products, seaweed) into uniform granules that improve soil health, store and transport easily, and meet market expectations for organic inputs.

Why an environmentally friendly organic fertilizer granulation plant matters

The global push for sustainable agriculture makes the concept urgent. Raw organic wastes are bulky, smelly, and often a disposal problem. Processing those wastes in an environmentally friendly organic fertilizer granulation plant transforms liabilities into assets:

it keeps nutrients on the land instead of letting them leach into waterways;

it reduces greenhouse gas emissions from unmanaged piles;

it creates a product with predictable nutrient content and handling properties preferred by modern farmers.

Granulated organic fertilizers combine organic matter and slow-release nutrient dynamics with the convenience of granular application — a sweet spot for both soils and supply chains.

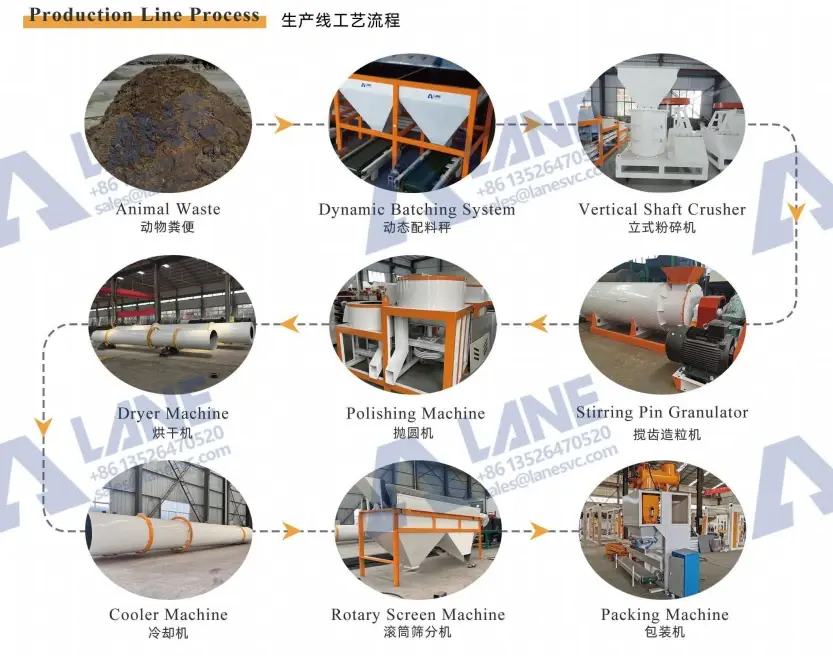

Typical process flow (how the plant works)

An environmentally friendly organic fertilizer granulation plant is a system of stages; each step is designed to sanitize, stabilize, and shape organic material into quality granules.

Feedstock reception & pre-treatment

Incoming raw materials (manure, straw, sludge, food waste, algae) are inspected and blended to target an appropriate carbon:nitrogen ratio. High-moisture feeds are sent to an inclined dewatering machine to remove excess water and reduce processing energy.

Composting / biological stabilization

Proper sanitation is crucial. The blended material moves to a composting area where crawler type compost turner or groove type compost turner ensures even aeration and thermophilic temperatures (55–65°C) to kill pathogens and seeds. Regular turning accelerates decomposition and stabilizes the organic matter.

Size reduction & homogenization

Partially composted material is crushed (semi-wet or hammer crushers) and mixed in a horizontal mixer to produce a uniform feedstock for granulation. Homogeneity improves granule quality and nutrient consistency.

Granulation

The stabilized material is granulated using equipment suited to the desired product: a stirring pin granulator for high moisture and organic binders, or a rotary drum granulator for continuous, high-capacity operation. Granulation binds particles into round, crush-resistant pellets.

Drying and cooling

Granules are dried in a rotary drum dryer to reduce moisture to safe storage levels, then passed through a rotary cooler to stabilize temperature and hardness.

Screening and polishing

A rotary screener separates oversized and undersized material. Oversized particles are recycled; qualified granules can pass through a polishing machine to improve appearance and reduce dust.

Quality control, packaging & storage

Samples are tested for nutrient content, stability and safety (pathogens, heavy metals). Final packaging is handled by automatic bagging lines; product labeling provides guaranteed analysis and application recommendations.

Key advantages

An environmentally friendly organic fertilizer granulation plant delivers a cluster of benefits that span environmental, agronomic and commercial domains:

Sanitation & compliance: High-temperature composting plus controlled processing reduces pathogens and helps meet regulatory standards.

Soil health: Granules supply organic matter and beneficial compounds that improve soil structure, water retention, and microbial life.

Application efficiency: Granules spread more uniformly than loose compost, enable mechanized application, and are easier to store and transport.

Marketability: Granular format is preferred by distributors and farmers — it supports branding (organic, slow-release) and premium pricing.

Waste management: Municipalities and food processors can reduce disposal costs while creating value from by-products.

Real-world examples

A regional poultry cooperative replaced raw manure spreading with a community-scale environmentally friendly organic fertilizer granulation plant. Odor complaints dropped, local water quality improved, and farmers gained a locally produced soil amendment they could sell or use.

A municipal wastewater utility partnered with a fertilizer company to co-compost sludge and green waste, granulate it, and supply urban landscapers with a certified organic soil conditioner — closing a civic waste problem while creating revenue.

Challenges and practical solutions

Feedstock variability: Organic wastes vary seasonally and chemically.

Solution: Blend streams, run frequent lab tests, and maintain flexible recipes.

Energy and water use (drying & dewatering): Removal of moisture is energy-intensive.

Solution: Use energy-efficient drying, heat recovery systems, solar pre-drying, and optimize dewatering (inclined dewaterers) to cut costs.

Public perception & regulation: Some end users distrust "sludge-derived" products.

Solution: Transparent quality control, pathogen testing, clear labeling, and certification (organic/compost quality standards) build trust.

Capital investment: Plant equipment is a major upfront cost.Solution: Phased projects, cooperative ownership, or public-private partnerships spread costs and risk.

Environmental and economic impact

An environmentally friendly organic fertilizer granulation plant can reduce landfill use, lower methane emissions from unmanaged waste, and help agricultural systems sequester carbon through added soil organic matter. Economically, granulation creates a product with higher unit value than raw compost, opening sales channels to retail garden centers, landscapers, and commercial farms.

An environmentally friendly organic fertilizer granulation plant is a practical, scalable piece of infrastructure for sustainable food systems. By combining biological stabilization (composting) with mechanical processing (granulation, drying, screening), these plants convert diverse organic wastes into safe, consistent, and marketable fertilizer granules. The result is cleaner communities, healthier soils, and new revenue streams for waste generators and farmers alike. With careful feedstock management, energy optimization, and transparent quality controls, granulation plants are a cornerstone technology for circular agriculture.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments