Compost-Based Granular Organic Fertilizer: The Future of Sustainable Crop Nutrition

- Efat Elahi

- Aug 15, 2025

- 4 min read

Compost-based granular organic fertilizer is not merely an agricultural input; it is a carefully formulated soil conditioner that combines the benefits of organic compost and the convenience and precision of granular fertilizers. Unlike bulky and unstable raw compost, this advanced form of fertilizer can provide uniform nutrient content, slow-release advantages, and is easy to apply.

From large farms to urban gardens, compost-based granular organic fertilizer is increasingly becoming the preferred choice for those who value soil health, sustainable production, and long-term productivity. The growing organic agricultural transformation and the enhanced environmental awareness of consumers have made it not only a practical option but also a strategic choice for agricultural producers.

What Is Compost-Based Granular Organic Fertilizer?

At its core, compost-based granular organic fertilizer starts with nutrient-rich compost—often made from green waste, livestock manure, food scraps, and agricultural residues. This base material is processed, refined, and granulated to form dry, uniform pellets or granules.

Common raw materials include:

Raw Material | Primary Benefit |

Poultry manure | High nitrogen content for leafy growth |

Cattle manure | Improves soil structure |

Crop residues | Adds organic matter and micronutrients |

Green waste (leaves, grass) | Balanced nutrient profile |

Food waste compost | Rich in diverse nutrients |

Biochar | Enhances nutrient retention and water holding capacity |

The result is a clean, easy-to-store product that provides consistent nutrient delivery and can be applied with standard fertilizer spreaders.

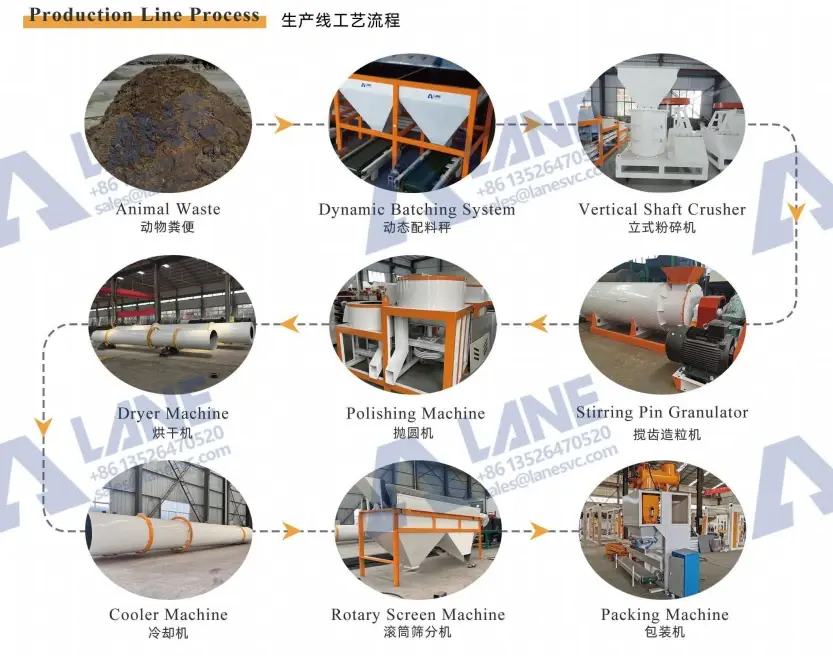

How It’s Made: From Compost to Granules

Composting – Organic raw materials are blended and decomposed using a wheeled compost turner or groove type compost turner, ensuring proper aeration, temperature control, and pathogen elimination.

Screening & Refining – A rotary drum screening machine or vibrating screener removes oversized debris and ensures a uniform particle size before granulation.

Granulation & Polishing – The prepared compost is fed into a rotary drum granulator, disc granulator, or stirring pin granulator to form uniform granules. These granules then pass through an organic fertilizer polishing machine, which smooths surfaces, improves appearance, and reduces dust — producing a cleaner, more marketable product.

Drying & Cooling – A rotary drum dryer lowers moisture content to safe storage levels, followed by a rotary drum cooler to stabilize temperature and prevent clumping.

Final Screening & Coating – Another rotary screening machine removes off-size particles. Granules may be coated in a fertilizer coating machine to enhance flowability and prevent moisture absorption.

Packaging – The finished compost-based granular organic fertilizer is bagged using an automatic packing scale or stored in bulk for distribution.

Key Advantages of Compost-Based Granular Organic Fertilizer

1. Enhanced Soil Health

Unlike synthetic fertilizers that can degrade soil over time, compost-based granular organic fertilizer builds organic matter, promotes microbial activity, and improves soil structure for long-term fertility.

2. Precision and Convenience

Granular form allows for accurate application rates, whether broadcast, side-dressed, or integrated into irrigation systems. No more messy handling like raw compost.

3. Sustainable Waste Management

By converting manure, crop residues, and organic waste into fertilizer, the system reduces landfill use, greenhouse gas emissions, and nutrient runoff.

4. Slow and Steady Nutrient Release

Granules release nutrients gradually, minimizing leaching and ensuring plants receive balanced nutrition throughout the growth cycle.

5. Cost-Effective and Scalable

From small farms to large agribusinesses, granulation makes organic fertilizer production and application more efficient, reducing transportation and storage costs.

Case Study: Transforming Poultry Waste into Profitable Fertilizer

A poultry farm producing over 100 tons of manure per month faced increasing disposal costs and environmental compliance pressure. By installing a LANE compost-based granular organic fertilizer production line, the farm turned its waste into a marketable product.

Results after one year:

Reduced manure disposal costs by 90%

Generated a new revenue stream through local sales to vegetable growers

Improved soil health on their own fields, increasing crop yields by 15%

Strengthened sustainability credentials, leading to better brand reputation

The farm’s experience shows how compost-based granular organic fertilizer production can be both an environmental and financial win.

LANE’s Expertise in Compost-Based Granular Organic Fertilizer Production Lines

LANE designs complete production lines to meet the requirements of raw material types, production capacity and end-user needs. From the re-pulping machine to the granulator, dryer and packaging machine, each piece of equipment is meticulously designed to be highly efficient, durable and easy to operate.

Our turnkey solution ensures a smooth transition from waste management to the production of value-added fertilizers, and provides professional installation, training and continuous technical service support. Whether you are starting on a small scale or conducting large-scale production, LANE can offer you a path towards sustainable and profitable fertilizer production.

A Smart Choice for Agriculture’s Future

The shift toward organic farming is more than a trend—it’s a necessity for sustainable food production. Compost-based granular organic fertilizer delivers consistent results, improves soil health, and supports a closed-loop agricultural economy.

By transforming organic waste into a high-value product, farmers not only meet market demand for chemical-free produce but also reduce environmental impact and operational costs. With the right equipment and expertise, this approach can redefine both farm profitability and ecological stewardship.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments