Beyond the Bag: How a Certified Production Line Guarantees Purity in Your Organic Fertilizer

- Efat Elahi

- Dec 30, 2025

- 5 min read

Table of Contents

Introduction

More Than a Label: What "Certified" Really Means

The First Defense: Aggressive Pre-Cleaning

The Purification Heart: Precision Bio-Oxidation

Engineering Purity into Every Granule

The Digital Shield: Traceability and Data

Purity as a System, Not a Slogan

Conclusion: Confidence, Rooted in Process

In the era of green agriculture and healthy food, organic fertilizer, as a core input for ecological planting, has become the first choice of more and more farmers and agricultural enterprises. However, the quality of organic fertilizer varies depending on the production method and quality control. Impure organic fertilizer may contain harmful substances such as heavy metals, pathogenic bacteria, and weed seeds, which not only fails to promote crop growth but also pollutes soil and water sources, and even endangers food safety.

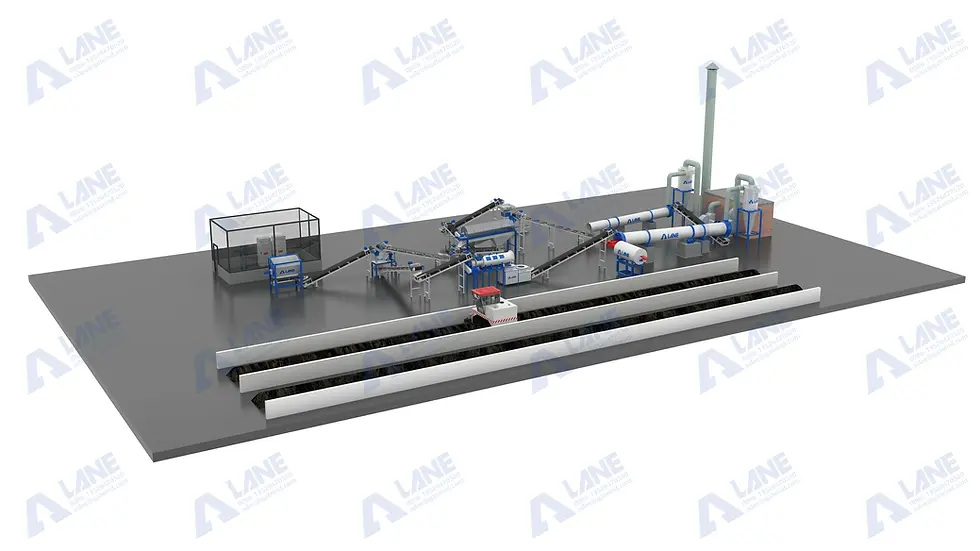

An organic fertilizer production line is required to create premium-quality organic fertilizer. LANE Heavy Industry, as a leader in the field of agricultural machinery manufacturing, creates certified organic fertilizer production line equipment. This article explores how the certified organic fertilizer production line goes beyond simple product packaging to ensure the purity of organic fertilizer.

More Than a Label: What "Certified" Really Means

A certified organic fertilizer production line represents a verified system of control. Certification from bodies like OMRI or under ISO standards is an audit of the entire process, not just the final product. It validates that every stage, from raw material intake to bag sealing, is designed and managed to prevent contamination, ensure complete sanitation, and produce a consistent, pure product. This systemic approach transforms purity from a hopeful outcome into a predictable, measurable result.

The First Defense: Aggressive Pre-Cleaning

The first step is the removal of non-organic elements from the raw materials like manure or green waste. Raw materials often contain physical contaminants—plastics, glass, stones, and metals. The LANE Pre-Shredder and Trommel Screen are used to shred the raw material and screen it for any non-organic matter. This step ensures that only clean, homogenized organic material proceeds to the production line.

The Purification: Precision Bio-Oxidation

In this stage, controlled fermentation happens. Here, heat-loving microbes naturally break down organic matter and, critically, destroy pathogens, weed seeds, and harmful bacteria. In a traditional composting system, this process is uneven and lengthy.

In a basic compost pile, this process can be uneven. In a certified organic fertilizer production line using a LANE Crawler Compost Turner or Fermentation Tank, the composting time is reduced to weeks from months. The LANE fermentation tank is an automated, controlled system with active aeration. This maintains the precise temperature (often above 55°C/131°F) and oxygen levels required to guarantee sanitization. The process is no longer left to chance; it is digitally monitored and logged. This stage is where biological purity is assured, transforming raw, potentially hazardous organic waste into a stable, sanitized humus.

Engineering Purity into Every Granule

Post-fermentation, the fermented compost is cured and then sent to the main certified organic fertilizer production line. Here, the product is first crushed into fine powder with the help of a Vertical Crusher. Then the compost is sent to the mixer, where it is mixed with any additional nutrients and binding agents like water according to your formulation. The resulting compost is then sent to the LANE Stirring Pin Granulator.

This stage is vital for purity preservation. By creating dense, uniform granules, the process minimizes dust. Dust creates potential cross-contamination and a loss of valuable nutrients; granules prevent that from happening. Furthermore, a LANE coating drum can apply a thin, natural coating to seal the granule. This locks in nutrients and prevents moisture absorption that could lead to microbial spoilage.

The Digital Shield: Traceability and Data

In a modern certified production line designed by LANE, a SCADA control system continuously logs data from every machine. It shows pre-cleaning efficiency, fermentation temperatures and durations, and drying parameters. This creates a digital audit trail required for fertilizer certification and labeling.

If any question ever arises about a batch, producers can trace it back to its exact raw material source and review every process parameter it underwent.

Purity as a System, not a Slogan

LANE Heavy Industry designs machinery with the hygiene and closed-system requirements of a certified production line as core principles. Features like easy-clean surfaces, enclosed conveyors, and automated process controls minimize human contact and intervention, which are primary vectors for contamination. Purity is engineered into the line’s physical layout and operational logic.

Conclusion: Confidence, Rooted in Process

The purity of your organic fertilizer is ultimately determined long before the bag is sealed. It is the direct result of investing in a certified production line—a meticulously engineered system where every piece of technology, from LANE’s rugged shredders to its intelligent control software, serves the singular goal of eliminating impurities and safeguarding integrity. By choosing products from manufacturers who utilize such systems, you gain more than just nutrients; you gain the confidence that your organic choice is genuinely pure, from the ground up.

FAQ

Q: As a consumer, how can I tell if a brand uses a certified production line?

A: Look beyond the "organic" label. Reputable brands often state certifications like OMRI Listed or ISO 9001 on their packaging or website. These certifications typically require an audited production process. Don’t hesitate to contact the company directly to ask about their manufacturing and sanitation protocols.

Q: Doesn't the high heat of composting kill all pathogens anyway?

A: It can, but only if the temperature is consistently high enough throughout the entire material mass for a specific duration. A rudimentary pile may have cold spots. A certified production line with automated turning and temperature monitoring guarantees that every particle reaches and maintains the critical temperature needed for complete sanitization, making pathogen destruction a certainty, not a possibility.

Q: What is the biggest contamination risk after the fertilizer is made?

A: Post-production handling and storage are key risks. A quality certified production line mitigates this by automating the final steps—using enclosed systems for cooling, direct transfer to automated bagging machines, and sealing bags immediately. This minimizes the product's exposure to potential environmental contaminants in the warehouse.

Q: Can small-scale producers achieve this level of certified purity?

A: Absolutely. The principles of a certified production line—controlled processes, sanitation protocols, and documentation—can be applied at various scales. While the machinery may be smaller, the commitment to systematic control is what defines the approach. Many certification programs have pathways for operations of all sizes.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Comments